Official Blog of Sierra--Let's Talk Flow!

Flow Meter Do’s and Don’ts with Ammonia

Editor’s Note: This post was originally published on April 25, 2012. Due to its popularity and continued questions on this issue, we updated the post on 2/2/2018.

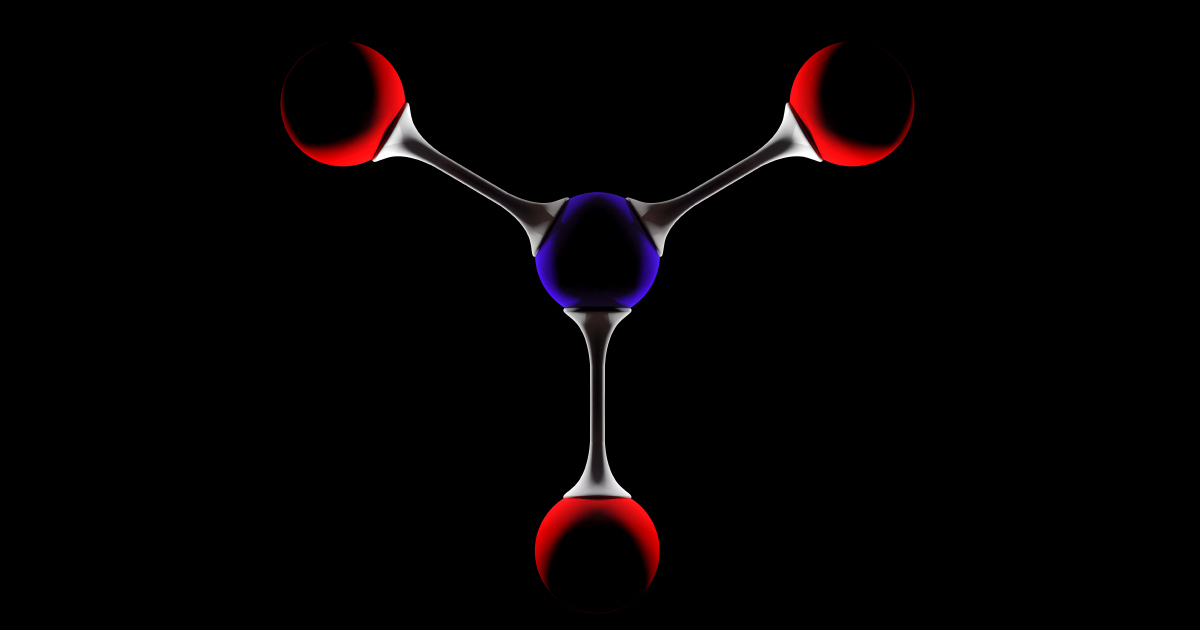

We often have engineers and researchers ask us about the best way to measure and control ammonia. We’ve got a perfect product for the application, but there are a couple of precautions that you have to take.

Some customers have run into the problem of ammonia turning from a gas into a liquid and ruining the flow meter they are currently using. Our SmartTrak 100 flowmeter is ideal for ammonia mass flow control. It’s carefully designed to assure that the materials are compatible with ammonia in its anhydrous (free from water) state.

How to prevent ammonia gas from converting to liquid

The key to ammonia, then, is that it has to remain dry and warm to keep it in its gaseous form and free from destructive gas sub-products. Even though a tank of ammonia is technically dry, vapor or liquid can still condense at critical plumbing points, mix with the ammonia, and form those gas sub-products that can attack 316 Stainless Steel and the Neoprene seal material.

Here are some ways to maintain the proper environment:

- Keep plumbing temperature above the dew point. Use heat tape at critical points to maintain a gas temperature of approximately 120°F (122°F maximum), especially where the gas enters meters and controllers. The maximum temp spec on SmartTrak is 122°F.

- Heat meter’s flow body. It’s important to heat the flow body as well. SmartTrak’s 316 stainless steel flow body should be heated to 115°F.

- Reduce valves and other components. These can cause sudden drops in pressure or increases in velocity, both of which may result in condensation.

- Check plumbing for leaks on a regular basis.

- Maintain low pressures. Lower pressures are desirable to keep ammonia in its gaseous state.

- Maintain regulators. Keeping regulators in prime condition and leak-free is critical to maintaining the correct pressure.

- Install high. Mass flow controllers and meters should be installed at high points in the process rather than at the bottom where moisture can collect.

If these safeguards are in place, Sierra’s meters and controllers will provide years of reliable service. Contact our experts in our Technical Support Department for further information.

Scott Rouse, Product Line Director

Sierra Instruments

Go to Autotest Division >

Go to Autotest Division > DOWNLOAD

DOWNLOAD