Official Blog of Sierra--Let's Talk Flow!

Part 2-Flow Energy Management Applications-Installation Tips & Tricks

In part 1 of our Flow Energy Management series, we identified the 3 Killer Flow Energy Management Applications that will reduce energy costs: compressed air & natural gas measurement, steam production, distribution, and allocation, and water/BTU measurement. And we identified the best flow meters for each of these applications: thermal mass flow meters for gas, vortex flow meters for saturated and super saturated steam, and clamp-on ultrasonic flow meters for liquid/water flows. If you haven’t read part 1 of this article, we recommend these 3 Killer Apps to Lower Energy Costs With Efficient Flow Energy Management.

Now that we have identified the best flow meter for each type of fluid and application, proper installation is key for successful flow readings. Many times if you think your flow meter “doesn’t work”, it could just be that the meter was not installed properly. In part 2 of our flow energy management series, we take a look at three tips and tricks to consider for successful installation:

- Thermal flow meter straight-run requirements

- Vortex flow meter installation mistakes to avoid

- How to select the right portable ultrasonic flow meter

Installation Tips For 3 Common Energy Flow Measurement Solutions

1. Overcoming Thermal Flow Meter Straight-Run Requirements

You have specified the correct industrial thermal insertion mass flow meter and are ready to install it within your application. Now what? Where do you place the meter for optimal performance? This is where technical expertise comes in, along with a mixture of science and tribal knowledge.

The primary installation question is: How much upstream and downstream straight run is required, and what happens if you use less straight run?

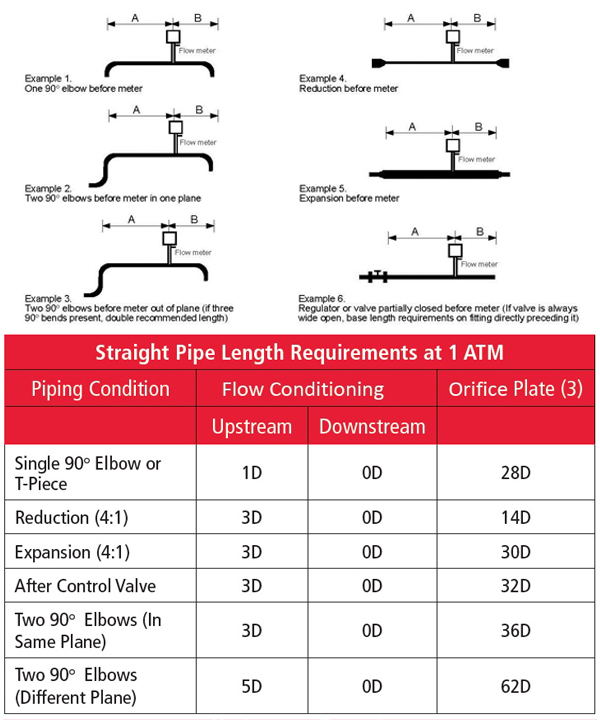

Because valves, elbows, control valves, and other piping components may cause flow disturbances, you want to select an installation site that will minimize possible distortion in the flow profile. Check your specific piping condition against the examples shown below.

In order to achieve accurate and repeatable performance, install the flow meter using the recommended number of straight-run pipe diameters upstream and downstream of the sensor. The chart below shows basic good plumbing practice for common upstream obstructions and meter locations.

What happens if you use less run than recommended?

Remember first that a thermal insertion mass flow meter probe is a “point-velocity” device and is only as good as the installation. It measures a velocity at a single point, and then the electronics multiply by the cross-sectional area to arrive at a flow rate.

The meter takes into consideration an average shape of the moving gas as it goes down the pipe. It assumes a fully-developed, bullet-shaped flow profile that is being measured at the highest velocity point at the leading edge, center.

In the case of an expansion fitting upstream (like Example 5 in the chart above), the danger is a “jet-stream” of gas shooting through the new, larger diameter section, that has not yet spread out uniformly. It is not possible to predict what will happen, nor to place a de-rated accuracy on the results. The results would most likely be noisy from the turbulent, tumbling gas. Again, it can’t be exactly predicted.

The best suggestion is to install it with 4/5 of the straight run ahead, and 1/5 after, and move the probe around, in and out, to come up with a map of the flow pattern. Hopefully, the largest flow will still be in the center, dropping off uniformly in both directions by about 15%.

Flow conditioning is the optimal solution

Another solution for insertion flow meters is to install flow conditioning plates in the flanges somewhere in the straight section, requiring three diameters of pipe run (two before, one after). This installation will totally disrupt the flow, creating a “flat” profile. The center point is now representative of the entire flow, and the meter will do a straight multiplication without accounting for a drop-off at the edges.

The best solution for constrained piping environments is to specify an inline thermal mass flow meter with integral flow conditioning elements inside the flange body. Watch this video to see how it works.

2. Vortex Flow Meter Installation Mistakes to Avoid

There are also common mistakes to avoid made when installing vortex flow meters that can affect flow accuracy and therefore affect your bottom line:

- Not having the proper upstream and downstream diameter. Over the thousands of installations of vortex meters we have seen, this is the number one installation problem. Unlike thermal flow meters, vortex meters do not work with flow condition plates, so they must have a straight run of pipe to function at optimal levels. In most installations, you need a straight run of at least 10 diameters upstream and 5 diameters downstream.

- Installing the vortex meter backwards. When installing a vortex flow meter, make sure the orientation of your meter is in the direction the flow, so your meter’s flow sensor can measure your fluid accurately. Most vortex flow meters have some type of flow direction indicator to help you point downstream. Our InnovaMass iSeries, for example, has a directional pointer and arrows on the flange to help point you downstream.

- Measuring the incorrect fluid type in the pipe. It seems like a no-brainer, but this is a more common mistake than you would think. In some situations, an end user might be measuring steam flow and think they are producing saturated steam, but in fact, they have a 50% over heat and are measuring superheated steam. With saturated steam, the pressure and temperature are linked together and move in concert together as conditions change. Whereas superheated steam has a tremendous amount of additional energy put in the steam in the form of heat. The two different flowing fluids need to be measured differently to assure accuracy.

- Don’t shutdown your steam flow to install a vortex flow meter Many insertion vortex flow meters have a retractor to make hot tap installation much easier. This means you can install the insertion vortex flow meter in large steam pipes with no process shutdown. Watch the video to get additional hot tap installation tips for the InnovaMass 241i insertion vortex flow meter.

3. Tips for ultrasonic flow meter installation

- Use Clamp-On Sensors for Field flexibility Fieldwork calls for flexibility in your equipment. Look for a liquid flow meter clamp-on sensors with a high-powered ultrasonic pulse and digital signal processing that requires just one set of transducers for a wide range of pipe sizes and materials like metal, plastic, and concrete. These baseline features allow you to use your portable ultrasonic flow meter for many different applications, pipe sizes, and materials in your process. As a result, there is only one instrument to master for many different flow measurement need.

- Portable ultrasonic flow meters offer for easy set up With a portable ultrasonic flow meter, you can use one liquid flow meter in several locations throughout your flow process. Because of the portable nature of the flow meter, your equipment should all fit in one carrying case. This makes transport from one location to the next painless. Hand-held devices allow users to easily and quickly program the menu, including instantaneous flow rate, positive total, negative total, net total, velocity, date and time, and daily flow results. Wireless Bluetooth-enabled android tablet PC devices make it even easier to control data acquisition and processing.

Look for portable flow meter with a complete measuring kit including:

- Carrying case

- Non-invasive clamp-on transducers with hand-held device

- Compact mounting racks (magnetic and cable mount) and coupling compound

- Fast set-up — 5 minutes or less! With easy set-up CD.

- Long battery life

You’ve reached your destination and you have your equipment set up to begin taking measurements — but your flow meter is unresponsive. There’s nothing worse than dealing with equipment that doesn’t function as it should when you really need it to. To solve this common problem, look for a portable ultrasonic flow meter that includes a rechargeable lithium-ion battery that supports continuous operation for a minimum of 16 hours. You need a flow meter that can last for those long days in the field.

Have questions about Liquid Flow Meters or Switches?

We can help answer your questions about flow energy management and flow energy applications. The experts at Sierra Instruments can answer any questions you may have about ultrasonic flow meters, volumetric vortex meters, and flow switches for liquids.

Follow this link to find a local representative now and get answers to any questions you may have about our products and services.

Scott Rouse, Product Line Director

Sierra Instruments

Go to Autotest Division >

Go to Autotest Division > DOWNLOAD

DOWNLOAD