Official Blog of Sierra--Let's Talk Flow!

How Does a Flow Meter Work?

A flow meter works by measuring the amount of a gas, liquid or steam that passes through or around the flow meter sensors. While flow meter sensors work in many different ways, the end goal is the same: Deliver the most accurate and repeatable flow measurements for the specific application, whether for general research, process control or semiconductor processing.

Flow meters measure either mass or volume. In a volumetric flow meter, the flow Q is equal to the cross-sectional area of the pipe, A, and the velocity of the flowing fluid, v: Q = A * v. In a mass flow meter the mass flow can be represented this way (where Q is the volumetric flow rate and ρ is the fluid density): ṁ = Q ∗ ρ

In many cases, especially in chemical reactions, combustion, or buying and selling gases, mass flow rate is the most important consideration.

How Different Types of Flow Meters Work

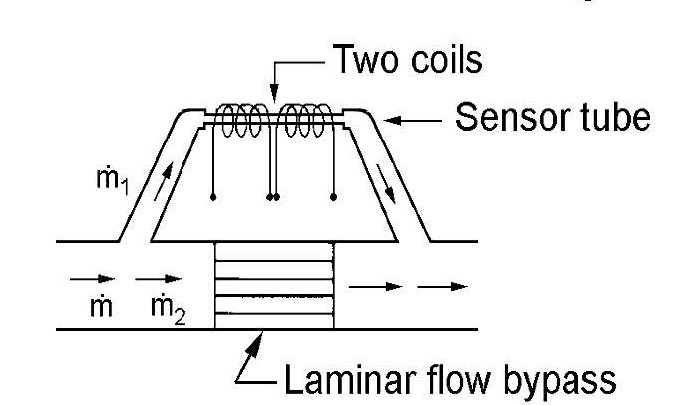

- Capillary Thermal Mass – Uses thermal heat transferred between gas flowing in a very small tube (the capillary) and a set of resistance temperature detectors (RTDs) to measure gas mass flow.

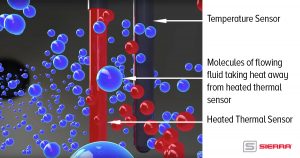

- Immersible Thermal Mass – Uses thermal heat transferred from a heated sensor that is immersed in the flow to measure gas mass flow.

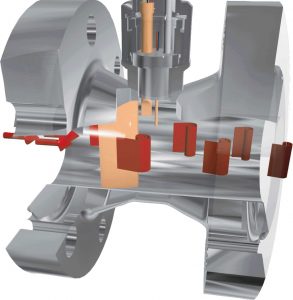

- Vortex Shedding – Uses vortices shed from a sensor immersed in the flow and a computed fluid density to measure volumetric and/or mass flow of gases, liquids and steam.

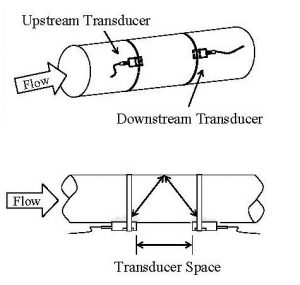

- Transit-Time Ultrasonic – Uses ultrasound to measure the speed of a fluid flowing in the pipe to measure volumetric flow and can be clamped onto the outside of the pipe so no pipe cutting is required

.

.

How Will the Flow Meter Be Used?

The next step is to determine what the flow meter is being used to measure:

- Gas, liquid or steam?

- Very large flows or only small flows?

- High or low temperature and pressure of the gas, liquid or steam in the pipe?

- Gases, liquids or steam flowing in big or complicated piping arrangements?

- Costly products that must be measured very precisely?

Depending on the answer to these questions, the best flow meter working technology can be selected. Some flowmeters work better when measuring different things.

- Thermal mass flow meters can precisely measure mass flow of gases from low to high flows.

- Vortex Shedding flow meters are ideal for measuring liquid and steam flows at high temperatures and pressures.

- Transit-Time Ultrasonic liquid flow meters are ideal for water or other liquid flow metering when no pipe cutting and process shutdown is ideal.

- Older technologies such as differential pressure, positive displacement or turbine meters also have their place.

For a full explanation of how these various industrial flow meters work, visit Sierra’s industry application resources page where you’ll find application stories, white papers, videos and selection tools that will help you select the best flow meter for your application.

Scott Rouse, Product Line Director

Sierra Instruments

Go to Autotest Division >

Go to Autotest Division > DOWNLOAD

DOWNLOAD