Official Blog of Sierra--Let's Talk Flow!

Part 3: Accurately Measuring Flare Gas — Managing Gas Mix Changes, Retaining Accuracy, Reducing Cost of Ownership

In my last post, I compared the pros and cons of the various flow meters available for measurement of flare gas. Ultimately, all but one has limitations that will impede your ability to accurately measure excess burn off from the hydraulic fracturing process. In this week’s post, I’ll share a new generation thermal mass flow meters that have the unique ability to adjust for changing flare gas mixture compositions in the field, offer cost savings, and still maintain excellent accuracy.

Flow Meter Flexibility and Accuracy

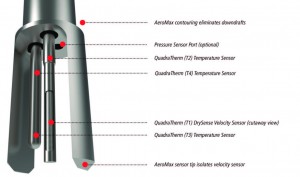

For the first time, new four-sensor thermal technology, branded QuadraTherm by Sierra, can compete with multi-path ultrasonic meters due to its ability to compute the mass flow rate of any gas mixture composition. As the composition changes through time, the instrument can be adjusted in the field in minutes without (as is required for traditional two-sensor thermal meters) having to send it back to the factory for recalibration. Driven by a hyper-fast microprocessor running an ever improving proprietary gas measurement algorithm set, branded qTherm by Sierra, mass flow rate of any gas mixture composition is computed in real time. In simplified terms, the microprocessor takes the inputs from the four sensors and qTherm solves the First Law of Thermodynamics (Heat Energy In = Heat Energy Out) for each data point. Four-sensor QuadraTherm (see Figure 1) has +/- 0.75% of reading accuracy for insertion probe versions—a nice improvement over the traditional 2.0% of reading in other thermal flowmeters. Further improving on this, the inline version of the instrument has an even better +/- 0.5% of reading accuracy.

For the first time, new four-sensor thermal technology, branded QuadraTherm by Sierra, can compete with multi-path ultrasonic meters due to its ability to compute the mass flow rate of any gas mixture composition. As the composition changes through time, the instrument can be adjusted in the field in minutes without (as is required for traditional two-sensor thermal meters) having to send it back to the factory for recalibration. Driven by a hyper-fast microprocessor running an ever improving proprietary gas measurement algorithm set, branded qTherm by Sierra, mass flow rate of any gas mixture composition is computed in real time. In simplified terms, the microprocessor takes the inputs from the four sensors and qTherm solves the First Law of Thermodynamics (Heat Energy In = Heat Energy Out) for each data point. Four-sensor QuadraTherm (see Figure 1) has +/- 0.75% of reading accuracy for insertion probe versions—a nice improvement over the traditional 2.0% of reading in other thermal flowmeters. Further improving on this, the inline version of the instrument has an even better +/- 0.5% of reading accuracy.

Avoid Costly Recalibration

In thermal mass flow meters, the gas mixture composition of the gas is required at time of purchase. Flare composition sampling depends on the wellhead and is typically done once every three months. Once the flare gas composition is known, operators can create, name, store and upload new proprietary gas compositions to the meter (see Figure 1). Accuracy is maintained without you having to send the meter back to the factory for costly recalibration. The meter itself stores four gas compositions. Operators can access the software’s gas library, which is password protected to keep proprietary gas mixtures secure. This gas library contains all AGA-compliant gas properties needed to make the algorithmic gas mass flow rate calculations.

Flow Measurement Cost Savings

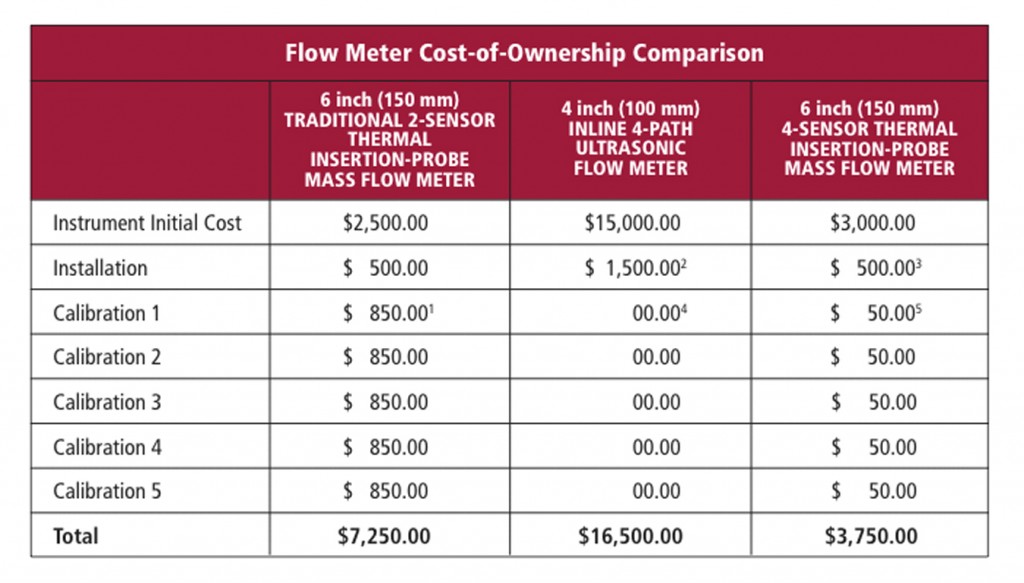

Both thermal and ultrasonic flow meters are preferred choices for flare gas measurement, but each has a different cost of ownership that should be understood. Let’s briefly review costs and overall cost of ownership. Table 1 gives a five-year cost of ownership example comparing a traditional 6.0 inch (150 mm) long two-sensor insertion-probe thermal mass meter inserted into a 4.0 inch (100 mm) flare header, with an inline 4” (100mm) four-path inline ultrasonic meter, and a 6 inch (150 mm) long four-sensor insertion-probe thermal mass meter inserted into a 4” (100 mm) flare header. The upfront cost of a four-path ultrasonic meter averages $15,000 (Flow Research, Inc. 2008 Study), while the four-sensor thermal insertion-probe meter averages $3,000. Insertion-probe thermal meters also accommodate larger pipe applications up to 72 inches (2m) with a single 0.75 inch (19mm) insertion point.

Ultrasonic meters only have in-line flow body configurations, and the cost increases exponentially with pipe size and number of paths. Using the Table 1 data, let’s assume that a typical customer has 150 flare gas measurement points. When the composition changes five times over the life of the wellhead, costs add up. Using four-path ultrasonic metering would be an upfront cost of $2,475,000, but the instrument would be unaffected by gas composition changes. In contrast, the four-sensor thermal meters would be much less expensive up front at $562,500, even though periodic field adjustments of the four-sensor thermal meter would be required. If you take a more macroeconomic view on the industry and make the reasonable estimate of 30,000 new flares per year that need measurement, annual ultrasonic metering costs are pushed to $495 million. Under these same assumptions, four-sensor thermal would cost much less at $112 million. These cost estimates support the need for alternative, lower cost metering choices for this tough application. In the absence of lower cost options, energy costs will increase over the long-term as higher metering costs are passed on to the consumer in the form of higher energy prices. Want to learn more about cost-effective, more accurate four-sensor air flow meters? Download my full white paper on Flare Gas Mass Flow Metering today. I hope you enjoyed this three part series over the last weeks and learned some valuable things that will prepare you for your next flare gas measurement opportunity.

Matthew Olin, President

Sierra Instruments

Go to Autotest Division >

Go to Autotest Division > DOWNLOAD

DOWNLOAD