Official Blog of Sierra--Let's Talk Flow!

Reducing Costs of Steam Flow Measurement

Traditionally, steam flow has been measured with a differential pressure device. This is typically an orifice plate. However, such devices are inherently volumetric flow measurements.

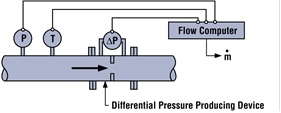

As we have discussed in previous blog posts, changes in pressure and temperature will change the mass flow rate of steam. Even a “small” change of 10% in steam pressure will result in a 10% error in non-compensated mass flow. This means that, in a typical differential pressure measurement installation, the volumetric flow rate measured by the device must be compensated by measuring temperature and pressure, and then these three measurements (ΔP, T and P) integrated with a flow computer to calculate mass flow.

Putting it all together, a “traditional” installation looks like this:

Costs of a Traditional Steam Flow Measurement Installation

- Pressure and temperature are not measured at the same point as flow. This will lead to errors in the mass flow. Remember a 10% error in pressure equals a 10% error in mass flow. If you are selling the steam in a custody transfer application, inaccuracies of 10% will cost you 10% of your profit!

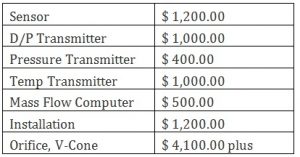

- High installation costs. You must buy a temperature sensor, a pressure sensor, the differential pressure device, and a flow computer. Multiple pipe penetrations are required, along with wiring and packaging the measurement system.

- High maintenance costs. The pressure sensing ports are prone to plugging, the orifice plate may wear out, and all the individual sensors will need periodic recalibration. Furthermore, troubleshooting such a complex system isn’t easy.

Choosing the Right Tool

In view of the above, the ideal tool for measuring steam flow would be a meter that has one pipe penetration, thus measuring temperature, pressure and volumetric flow at the same point, and has onboard processing to calculate mass flow. Sierra’s InnovaMass® iSeries vortex flow meter does exactly that.

Vortex is the ideal flow technology for gas, liquid, and steam measurement. Sierra’s InnovaMass vortex flow meters can be specified to measure up to five process variables with one process connection: volumetric flow, mass flow, density, pressure, and temperature. With this multivariable capability, it’s easier to maximize your steam productivity and reduce cost-of-ownership.

Sierra’s next generation InnovaMass iSeries (240i inline and 241i insertion) features a new hyper-fast microprocessor, robust software apps, and an automated state-of-the-art manufacturing and flow calibration facility to assure the highest level of quality and delivery.

So what is the bottom line? The cost of measurement for a traditional ΔP meter adds up quickly:

Learn more about reducing the cost of steam flow measurement today. Sierra’s InnovaMass iSeries inline version can be acquired for as little as $2,400 for a single unit and well under $2,000 if multiple units are needed.

Matthew Olin, President

Sierra Instruments

Go to Autotest Division >

Go to Autotest Division > DOWNLOAD

DOWNLOAD