Each day, millions of tons of municipal solid wastes are disposed of in sanitary landfills and dump sites around the world. Over 1,200 landfills worldwide collect landfill gas, which reduces greenhouse gas emissions and accrues emissions credits to meet the Environmental Protection Agency’s (EPA) reporting standards. Many also use this captured biogas as a clean energy source in the cogeneration process.

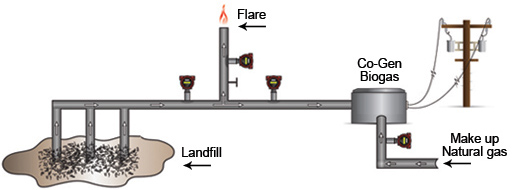

Solid wastes from households, commercial and industrial activities enter a landfill, where bacteria decompose the organic material. A by-product of the bacterial decomposition is biogas, composed of 50% methane and 50% carbon dioxide. To collect this landfill gas, a series of pipes are embedded within the landfill and a "flare" is used to burn off the collected gas. For cogeneration, this gas is compressed and mixed with natural gas, which in turn can be used to run a power generator.

SIERRA'S SOLUTION

Most companies are interested in measuring the biogas as it leaves the landfill, but this is difficult. Low pressure makes differential pressure (dP) devices like orifice plates unsuitable since they require a fairly large differential pressure to operate. Also, the landfill gas is often very dirty with a high moisture and particulate content. This can clog up devices like annubars and orifice plates and gum up turbine meters and similar instruments that have moving parts.

With an installed base of over 40,000 instruments, Sierra's SteelMass™ 640S is helping companies accurately measure biogas for EPA reporting and control gas blending for cogeneration. The insertion design eliminates pressure drop, has no moving parts, and can measure both high and low flows with a 100:1 turndown.

With no moving parts to clog with dirty, particulate laden gas and a self-cleaning purge option for dirty flow environments, the SteelMass 640S maintains accuracy and lowers maintenance costs. The SteelMass sensor automatically corrects for changes in gas temperature and pressure, eliminating the need for separate temperature and pressure transducers. Sierra's SteelMass 640S is the flagship of North America's best-selling thermal mass flow meters. 2009 Flow Research Study, Yoder

Here's what makes Sierra's SteelMass 640S an ideal choice:- Optimized for methane (CH4) as well as N20, SF6, HFCs, PFCs and CO2, per the EPA mandate

- Generates nominal pressure drop across the immersible sensor probe

- Measures mass flow directly with one instrument

- Has a 100:1 turndown to measure low and high flows

- Self-cleaning purge option for dirty flow environments

- Easy, hot tap installation with a low cost-of-ownership

- Backed by a lifetime sensor warranty and proprietary Dry-Sense™ Sensor Technology

DOWNLOAD

DOWNLOAD