To mitigate greenhouse gas emissions, many companies reuse their biogas for cogeneration, but the amount of biogas produced often exceeds the amount needed for cogeneration. In such cases, it is often not economical to purify, compress and store the gas for later use, so it is flared off. Accurate mass flow instrumentation is essential for these companies to comply with the new EPA requirements.

Measuring the mass flow of flare gases presents several challenges:

- The flare may be in a large diameter stack or duct with distorted or swirling flow profiles

- Flows that range from very high to very low make differential pressure (dP) devices inaccurate because of poor turndown (4:1)

- Dirty, wet or hot flow can plug the holes in dP devices like annubars

- Stack piping may be difficult to access

SIERRA'S SOLUTION

Sierra's innovative MultiTrak™ 670S Thermal Mass Flow Meter is specially equipped to help companies accurately report flare gas emissions for the EPA (CFR Part 98) requirements. The MultiTrak performs optimally in dirty gas streams, has a high 100:1 turndown, and gives accurate measurements in applications with wide temperature ranges up to 400°C (750°F) and rapid velocity changes.

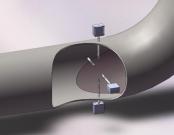

The MultiTrak 670S provides high accuracy in large ducts or stacks that have non-uniform velocity profiles. It consists of up to four 640S flow meters linked via Modbus, one control panel with touch-screen Human Machine Interface (HMI) and 4-20mA/0-5VDC output, and the associated cables for daisy-chaining the 640S flow meters. With this multipoint configuration, the MultiTrak dynamically compensates for changes in the flow profile in large pipes to instantaneously measure average mass velocity. It also allows users the ability to compensate for flow profile distortions by positioning the sensors in optimal locations.

Unlike most other multipoint systems, the individual sensor points of the 670S can be removed for service or repair without shutting down the system, which saves time and money on operating and maintenance costs.

Here's what makes Sierra's MultiTrak 670S an ideal choice:- Dynamically compensate for non-uniform flow profiles with user-friendly Human Machine Interface (HMI)

- Has 100:1 turndown providing accurate readings at very low and high flows

- Probes may be removed for service or cleaning without loss of measurement to lower cost-of-ownership

- Direct mass flow measurement

- No moving parts to clog decreases maintenance costs

- Patented Dry-Sense™ Sensor Technology holds calibration over time

DOWNLOAD

DOWNLOAD