Thermal Energy/BTU Ultrasonic Flow Meters Improve Energy Efficiency HVAC System

Almost every facility, campus, or hospital in the country has a HVAC process that heats and cools the building. With the current hot topic of improving energy efficiency, how do facilities managers and facilities engineers know that their HVAC process is running as efficiently as possible and not wasting energy? The key is to calculate the thermal energy/BTU of the system.

How do you calculate the Thermal Energy/BTU ?

The best solution is to use a clamp-on ultrasonic flow meter with thermal energy/BTU capability. A critical element of any thermal energy/BTU flow energy measurement is determining the amount of heat transferred between the cold and hot flow legs of an HVAC process. Often with only a small difference in temperature between the two flow legs, a precise measurement makes a huge difference. From this data the ultrasonic flow meter calculates the thermal energy BTU measurement of the system.

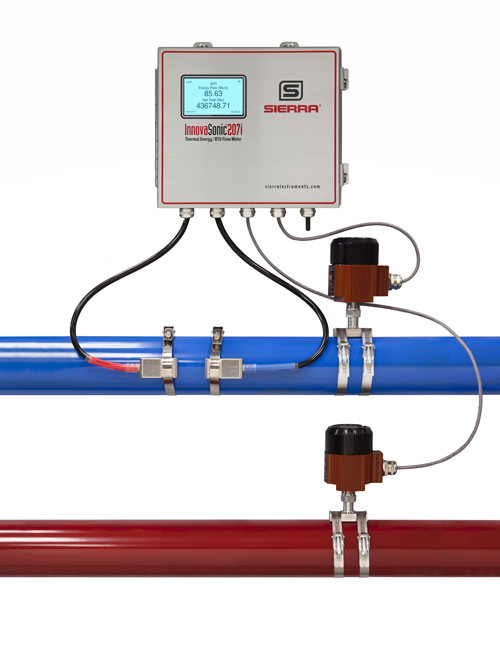

Figure 1. 207i ultrasonic liquid flow meter with transducers and clamp-on RTDs thermal energy/BTU

What to Look for in Ultrasonic Thermal Energy/BTU Flow Meter Selection?

High Accuracy

The most advanced ultrasonic flow meters, like Sierra’s InnovaSonic 207i, take into account the temperature difference as well as all NIST traceable fluid properties required to accurately measure flow and make ultra-precise temperature measurements between the cold and hot flow legs. Since transit-time ultrasonic flow meters measure liquid flow rate by detecting the speed of sound in the liquid, a small change in liquid density will impact the speed of sound measurement and thus impact accuracy. Unlike other ultrasonic meters that assume a fixed liquid density, the 207i calculates liquid density in real-time by adding a temperature input from a transmitter provided by Sierra or by using an external input from an existing transmitter. This ensures accuracy of +/-0.5% of reading from 0.16 to 40 ft/s (0.05 to 12 m/s) even if liquid density changes as the temperature of a flowing liquid moves up and down over time.

Flexibility & Ease-of-Use

For ease of use and installation, look for ultrasonic flow meters that come with a comprehensive software package of apps, field upgrades, and calibration validation. To make installation easy, the 207i has a unique visual sensor spacing tool on the local display, or software app, that allows end users to slightly move the sensors together or apart to position an indicator line between “goal posts” to ensure optimal signal strength. This gives peace of mind that the meter is installed correctly and ready to measure flow. Software apps offer engineers and operators apps like MeterFit™ to help optimize signal strength to ensure best performance. EnergyPro™ allows you to fully configure your thermal energy/BTU flow energy measurement system, including data-logging and totalization of all energy functions. Apps like ValidCal™ Diagnostics make field calibration validation easy. Engineers and operators can use apps for easy setup, field upgrades, and validation of hardware and firmware.

Lowest Cost-of-Ownership

Clamp-on ultrasonic flow meters make installation easy and cost effective – no pipe cutting or expensive plumbing. This also means that there is no downtime to the system which saves on maintenance costs.

[VIDEO] Learn Tips on How to Use Ultrasonic Flow Meters with Thermal/BTW Capability to Assess Energy Efficiency of HVAC System

After choosing the perfect ultrasonic flow meter, the key to assessing the efficiency of your HVAC system is to determine the temperature differential of the hot and cold legs of your system. If the temperature differential between your hot and cold legs is not as expected, you may have a problem with your pipe insulation or heat exchanger. These critical measurements give you information to fix your system and save money.

Watch our recent Flow Tip Video, “Energy Efficiency in Hot/Chilled Water BTU” by Glen Coblentz, VP of Sales, to learn more tips on how to use the 207i InnovaSonic ultrasonic flow meter with thermal BTU capability to assess the energy efficiency of your HVAC system and make smart energy saving decisions.

Benefits of InnovaSonic 207i Ultrasonic Flow Meter for Hot/Chill Water Measurement

Designed, built and calibrated for non-intrusive liquid flow metering, the 207i transit-time ultrasonic flow meter with thermal energy BTU capability is an ideal solution for determining the hot/chilled water BTU of your system. This provides facility managers with the high quality flow energy data required to manage energy costs.

- Clamp-on or insertion transducers measure bi-directional flow

- One meter for a wide range of pipe sizes from 2 to 236 inches (5.0cm to 6.0M)

- Accuracy +/- 0.5 percent of reading from 0.16 to 40 ft/s (0.05 to 12 m/s)

- Clamp-on or insertion PT 100 temperature inputs for thermal energy/BTU measurement

- Software apps for easy set up for optimal signal strength

- Upgrade meter firmware and software in the field

The InnovaSonic 207i is also part of Sierra's Big-3 iSeries, one complete flow energy management solution for any gas, liquid, or steam flow measurement.

Go to Autotest Division >

Go to Autotest Division >