Avoid Common Flow Meter Installation Mistakes to Optimize Flow Meter Performance

In our last blog, we discussed how plant and operation managers are searching for ways to manage the flow energy in their facility to cut costs and increase their process efficiency.

After the purchase decision is made, correct installation and calibration are the next steps to maintaining the equipment over the lifetime of the product and lowering the cost of ownership to increase the cost savings of the facility overall. Let's look at three common installation mistake to avoid and other ways to ways to lower cost of ownership and optimize your flow meters' performance.

Avoid Common Installation Mistakes

Once you have identified the right flow meter for each type of fluid and application, proper installation of your flow meter is critical for successful flow readings. Many times, if you think your flow meter “doesn’t work,” it could just be that the meter was not installed properly. Here are some installation tips for thermal mass, vortex, and ultrasonic flow meters:

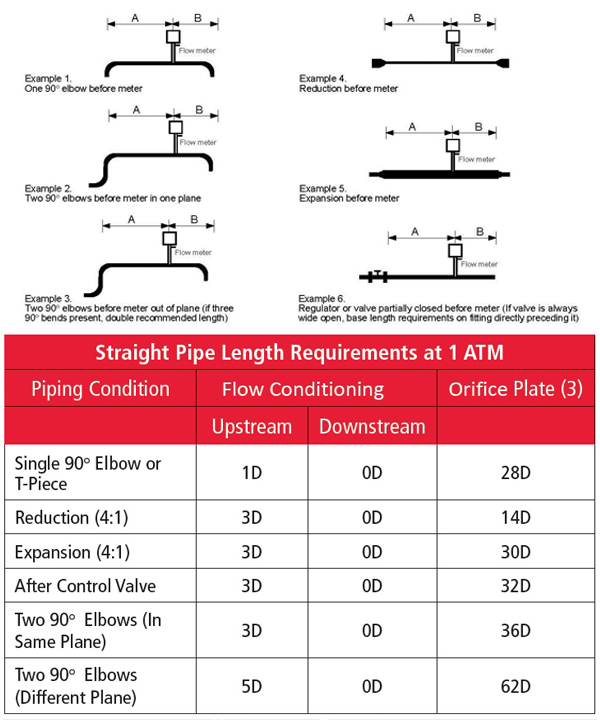

- In order to achieve accurate and repeatable performance for thermal mass flow meters, install the flow meter using the recommended number of straight-run pipe diameters upstream and downstream of the sensor. The chart below shows basic good plumbing practice for common upstream obstructions and meter locations.

Another solution for insertion flow meters is to install flow conditioning plates in the flanges somewhere in the straight section, requiring three diameters of pipe run (two before, one after). This installation will totally disrupt the flow, creating a “flat” profile.

2. Avoid the following mistakes when installing vortex flow meters:

-

- Not having the proper upstream and downstream diameter. Unlike thermal flow meters, vortex meters do not work with flow condition plates, so they must have a straight run of pipe to function at optimal levels. In most installations, you need a straight run of at least 10 diameters upstream and 5 diameters downstream.

- Installing the vortex meter backward. When installing a vortex flow meter, make sure the orientation of your meter is in the direction the flow, so your meter’s flow sensor can measure your fluid accurately. Most vortex flow meters have some type of flow direction indicator to help you point downstream.

- Measuring the incorrect fluid type in the pipe. In some situations, an end user might be measuring steam flow and think they are producing saturated steam, but in fact, they have a 50% over heat and are measuring superheated steam. (add link to blog explaining this)

- Don’t shutdown your steam flow to install a vortex flow meter. Many insertion vortex flow meters have a retractor to make hot tap installation much easier. This means you can install the insertion vortex flow meter in large steam pipes with no process shutdown.

3. For ultrasonic flow meters, consider clamp-on sensors for field flexibility and offer for easy setup. With a portable ultrasonic flow meter, you can use one in several locations throughout your flow process. Fieldwork calls for flexibility in your equipment. Look for a liquid flow meter clamp-on sensors with a high-powered ultrasonic pulse and digital signal processing that requires just one set of transducers for a wide range of pipe sizes and materials like metal, plastic, and concrete.

In-Situ Calibration Increases Throughput & Avoids Costly Shutdowns

The measurement accuracy of your device is critical in determining efficiency, performance, and cost-savings. So the more accurate your flow meter is the better data you have to make cost saving decisions. Thermal mass flow meters with in-the-field in-situ calibration validate the meter's accuracy without shutting down the facility. Learn how In-Situ calibration works in this video.

Learn more about how to manage the flow energy in your facility.

Download Flow Energy Guide for additional details on managing flow energy in your facility.

Watch Videos on how to measure air, gas, and steam better in your facility.

Go to Autotest Division >

Go to Autotest Division >