Physical Vapor Deposition (Sputtering)

Made easy with SmartTrak and Compod

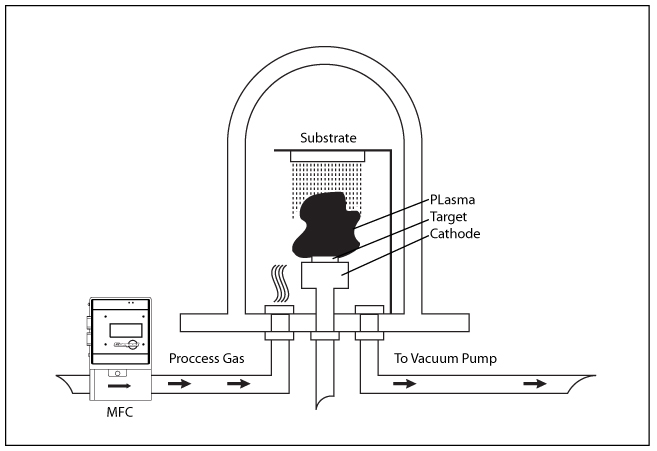

With a SmartTrak mass flow controller upgraded with Compod, PVD is made easy. Physical vapor deposition (PVD) or sputtering is commonly used for creating films of material on a substrate in the solar energy and semiconductor Industry.

In the PVD process, a negatively charged electrode is slowly disintegrated by molecular bombardment. The PVD medium is typically argon because this gas generates sufficient momentum to free atoms from the target. In a vacuum environment, these free target atoms deposit themselves on the surface of the material and form the desired coating or plating.

Maintaining a specified gas mass flow rate to the vacuum chamber is critical during the PVD process. Typically, vacuum pumping stations require a throttle valve or orifice-limiting device to control the pump's output when the PVD gas is introduced. This method is extremely pressure sensitive and can result in inefficient gas delivery and poor product quality.

Compod automatically compensates for changes in system pressure (vacuum pump fluctuations) or loss of pressure from the gas source (cylinder depletion). The SmartTrak MFC with Compod delivers precisely controlled gas mass flow rate to the vacuum chamber to maintain high quality end-product.