How Does a Flow Meter Work?

How Different Types of Flow Meters Work

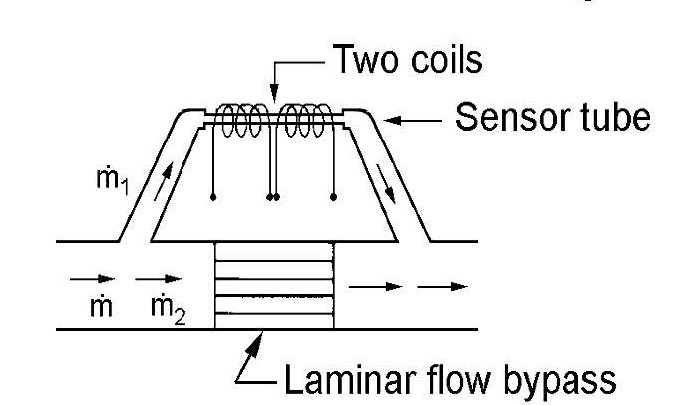

- Capillary Thermal Mass - Uses thermal heat transferred between gas flowing in a very small tube (the capillary) and a set of resistance temperature detectors (RTDs) to measure gas mass flow.

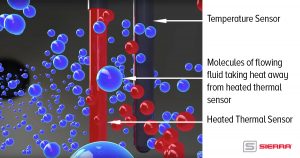

- Immersible Thermal Mass - Uses thermal heat transferred from a heated sensor that is immersed in the flow to measure gas mass flow.

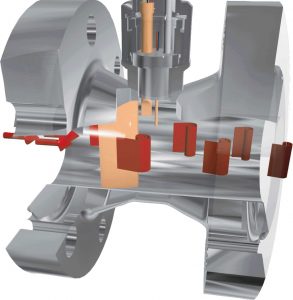

- Vortex Shedding - Uses vortices shed from a sensor immersed in the flow and a computed fluid density to measure volumetric and/or mass flow of gases, liquids and steam.

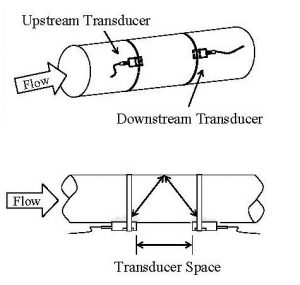

- Transit-Time Ultrasonic - Uses ultrasound to measure the speed of a fluid flowing in the pipe to measure volumetric flow and can be clamped onto the outside of the pipe so no pipe cutting is required

.

.

How Will the Flow Meter Be Used?

The next step is to determine what the flow meter is being used to measure:- Gas, liquid or steam?

- Very large flows or only small flows?

- High or low temperature and pressure of the gas, liquid or steam in the pipe?

- Gases, liquids or steam flowing in big or complicated piping arrangements?

- Costly products that must be measured very precisely?

- Thermal mass flow meters can precisely measure mass flow of gases from low to high flows.

- Vortex Shedding flow meters are ideal for measuring liquid and steam flows at high temperatures and pressures.

- Transit-Time Ultrasonic liquid flow meters are ideal for water or other liquid flow metering when no pipe cutting and process shutdown is ideal.

- Older technologies such as differential pressure, positive displacement or turbine meters also have their place.

Go to Autotest Division >

Go to Autotest Division >