Official Blog of Sierra--Let's Talk Flow!

For Improved Accuracy in Industrial Applications: Clean & Test Your Mass Air Flow Sensor

In today’s dirty heavy industrial applications, engineers and operators are often faced with an inherent challenge which affects mass flow accuracy: How do I know if the sensor of my mass flow meter is clean? and How do I clean the sensor without shutting down the system?

Because accurate mass flow readings are often critical for running an efficient system, you need to be able to count on the accuracy of the mass air flow sensor. In industrial applications, debris build-up can lead to false readings. Deposits of soot or dirt and dust can form an insulating blanket around the sensor, which of course is not good for a thermal sensor that works by measuring the heat lost to the flowing gas. This means thermal probes may need to be cleaned periodically to get the best flow measurement accuracy.

4 Ways to Clean Your Thermal Sensor

1. Remove the probe from the pipe (hot tap fittings may be used for this) or via a built-in purge system.

2. If the probe is covered with dirt or dust, blow off the sensors with high pressure (HP) air, or use a clean cloth to remove any dirt on the sensor. If you cannot remove the sensor from the pipe, a built-in purge system allows you to blow off the sensors without removing the probe by directing HP air onto the sensors to blow dirt or soot away.

3. Another improvement on this design is using axial flow sensors (sensors parallel to the flow) vice perpendicular flow. The use of axial flow sensors lessens the area on which debris can build up. Sierra has successfully used this design, coupled with a built-in purge system, to measure very dirty combustion air to coal fired power plants and for process air in tire manufacturing plants.

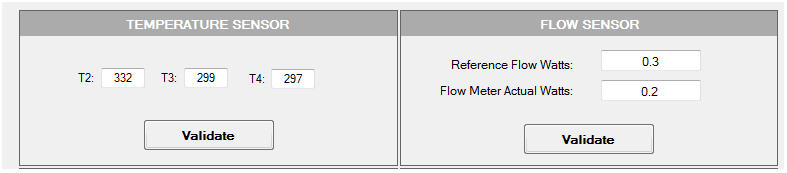

If those steps don’t solve the problem, check the sensor for other damage. For example, you can test the sensor with a volt meter to measure the ohm resistance across the wire of the sensor. Sierra has developed a software program that can validate a QuadraTherm sensor without disconnecting the sensor from the mass air flow meter. See the image below for a sample screen shot of the validation program.

This software is conveniently included with your QuadraTherm 640i/780i Mass Flow Meter order. You can also download the software. So remember if you have a dirty application all is not lost. Sierra has the hot tap, purge, or axial flow sensor solution and validation software to solve your problems.

Maryadine Washington, Mar-Com Manager

Sierra Instruments

Go to Autotest Division >

Go to Autotest Division > DOWNLOAD

DOWNLOAD