Voice of the Customer: Flow Meter Solution for Air Pollutant Measurement

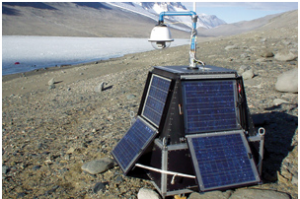

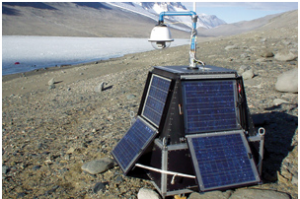

[caption id="attachment_3881" align="aligncenter" width="300"] Carbon Soot Aethalometer (South Pole)[/caption]

Carbon Soot Aethalometer (South Pole)[/caption]

To follow up on his progress, we asked Dr. Hansen a few questions about how his work provides accurate data to learn more about climate change and air pollution.

1. Describe your area of expertise. We manufacture a scientific instrument that measures air pollution by “black carbon” particles—now shown to be the No. 2 cause of global climate change. We also engage in scientific and technical research to improve the measurement of this pollutant.

2. What problems have you been attempting to tackle with your current or recent research studies?

Measurement of air pollution at challenging locations, including the:

Carbon Soot Aethalometer (South Pole)[/caption]

Carbon Soot Aethalometer (South Pole)[/caption]

- South Pole. -50°C, 3200 m. altitude, extremely clean air, zero humidity.

- South China and India. Extremely polluted air, very high ambient humidity, very dirty working environment.

Go to Autotest Division >

Go to Autotest Division >