Core Technology Series: Capillary Tube Thermal Mass Flow Meters and Controllers

Understanding Capillary Tube Thermal Mass Flow Meters & Controllers:

Flow meters and controllers are used every day in general purpose industrial and laboratory applications and in the semiconductor industry. Have you ever wondered how capillary tube flow meters work? or How to specify the perfect flow meter for your application? I am excited to present this ongoing core technology series based on excerpts from Sierra's Founder and Chairman (Also my Father), Dr. John G. Olin's, white paper entitled, “Capillary Tube Thermal Mass Flow Meters & Controllers- A User’s Guide.” This "User's Guide" is designed to educate both flow beginners and experts in the most common types of direct mass flow thermal flow meters, typical applications, principle of operation of capillary tube thermal flow meters, best practices for users, including the selection, installation, and operation of the instruments. Now let's start at the beginning.

What is a Capillary Tube Thermal Mass Flow Meter or Controller?

Capillary tube thermal mass flow meters directly measure the mass flow rate of clean gases and gas mixtures in lower flow ranges. A capillary tube thermal mass flow controller adds an integrally mounted flow control valve to the flow body of the mass flow meter and both monitors the mass flow rate and controls it to be equal to a set-point value selected by the user.

History of Capillary Tube Thermal Mass Flow Meter and Controllers

Capillary tube thermal mass flow meters and controllers were first commercialized in the early 1960’s. The space industry was one of the first users, but before long the industry that fabricated solid state semiconductor devices recognized their usefulness. When integrated circuit semiconductor devices began their long and continuing period of exceptional growth, the market for capillary tube thermal mass flow controllers grew with it. In the 1970’s and 1980’s, general industry recognized the advantages of using capillary tube mass flow meters and controllers in a broad range of applications, and several new companies were formed to serve this growing market. The advantages of accuracy, compactness, reliability, and cost-effectiveness continue to make capillary tube thermal instruments the choice for monitoring and controlling smaller mass flow rates of clean gases in general industry and in the fabrication of semiconductor devices.

Capillary tube thermal mass flow meters and controllers were first commercialized in the early 1960’s. The space industry was one of the first users, but before long the industry that fabricated solid state semiconductor devices recognized their usefulness. When integrated circuit semiconductor devices began their long and continuing period of exceptional growth, the market for capillary tube thermal mass flow controllers grew with it. In the 1970’s and 1980’s, general industry recognized the advantages of using capillary tube mass flow meters and controllers in a broad range of applications, and several new companies were formed to serve this growing market. The advantages of accuracy, compactness, reliability, and cost-effectiveness continue to make capillary tube thermal instruments the choice for monitoring and controlling smaller mass flow rates of clean gases in general industry and in the fabrication of semiconductor devices.

The primary virtue, and the source of their prominence, is the fact that capillary tube thermal instruments directly measure mass flow rate, as opposed to, for example, volumetric flow rate. This is important because most industries need to measure and control the flow of the molecules, i.e., the mass, of the gas entering their process.

Types of Direct Mass Flow Meters & Applications

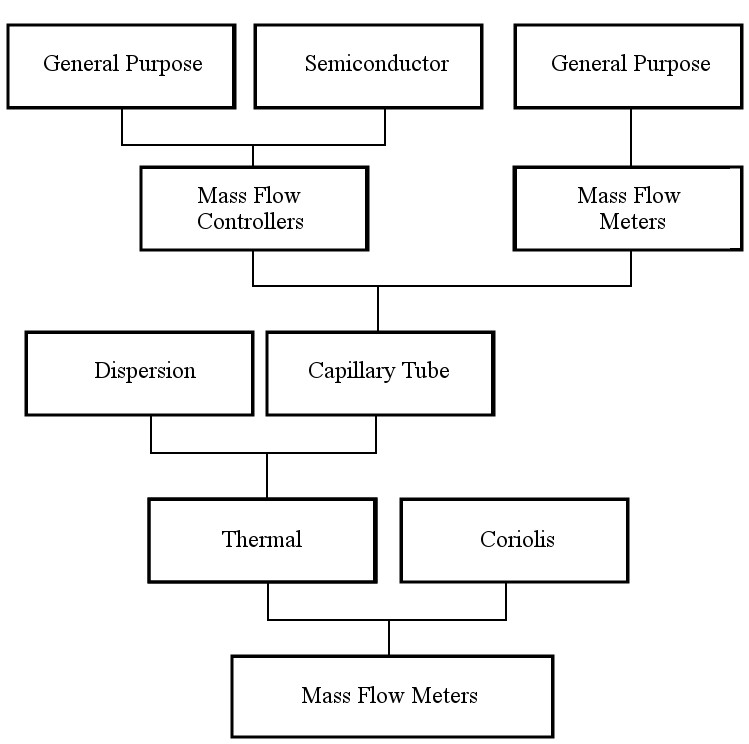

Figure 1: Classifications of Mass Flow Meters[/caption]

There are two kinds of flow meters that directly measure the mass flow rate of fluids---Coriolis mass flow meters and thermal mass flow meters. Coriolis mass flow meters directly measure the mass flow rate of most fluids, both liquids and gases, and do not require knowledge of the identity, or composition, of the fluid. Thermal mass flow meters directly measure the mass flow rate of gases, and do require knowledge of its composition. Coriolis mass flow meters have high accuracy, high pressure drop, work best with liquids, and are relatively expensive. Thermal mass flow meters have medium to high accuracy, low pressure drops, work best with gases, and are relatively inexpensive.

For the purposes of this blog series we will focus on thermal mass flow meters. Specially, capillary tube flow meters and controllers. Capillary tube thermal mass flow meters and controllers have two broad fields of application: general purpose industrial and laboratory applications and semiconductor manufacturing and other high purity vacuum processes. More MFCs are manufactured than MFMs because most users want to control the mass flow rate of the gas in their process rather than just monitor it. Capillary tube thermal MFCs offer a cost-effective solution for controlling the flow of gases because they are compact, require only one penetration of the process line, and have a built-in optimized control system.

Principle of Operation: How Capillary Tube Mass Flow Meters & Controller Work

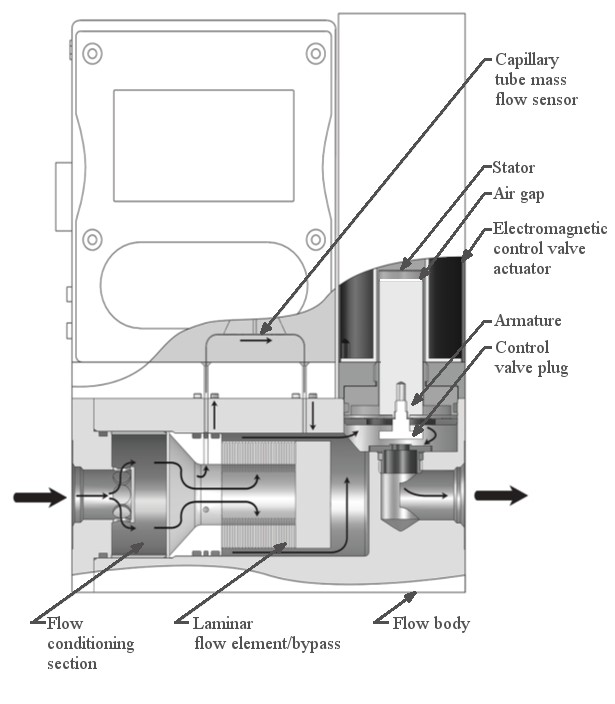

Figure 2: Typical general purpose mass flow controller

In the case of the capillary tube type of thermal mass flow meter (MFM) described in this blog, the flow enters the flow body and splits into two internal flow paths. One path flows through a heated capillary sensor tube that has a small diameter and relatively long length. The second parallel path inside the flow body passes through a split-flow bypass consisting of a laminar flow element that shunts the bulk of the flow around the sensor tube. The ratio of the flows through the bypass and the sensor tube is a constant. The capillary sensor tube measures its internal mass flow rate by means of the heat capacity of the gas that carries heat from an upstream resistance-temperature-detector winding to a downstream winding, both on outside of the sensor tube. The difference in the electrical resistances of the two windings provides the measurement of the mass flow rate through the sensor tube, and thereby the total mass flow rate in the flow conduit.

A capillary tube thermal mass flow controller (MFC) adds an integrally mounted flow control valve to the flow body of the MFM and both monitors the mass flow rate and controls it to be equal to a set-point value selected by the user either remotely or on the MFC itself. To learn more about Capillary Thermal Mass Flow Controller & Meter technology, watch this video that follows a molecule of gas through a typical capillary thermal flow controller.

Next up in the "Capillary Tube Thermal Mass Flow Meters & Controllers- User’s Guide" series, Dr. Olin describes the mechanical components of mass flow meters and controllers and the operation of these components.

Get more information on Capillary Tube Mass Flow Meters and Controllers:

Read more about the History & Evolution of Mass Flow Controllers Read Core Technology: Capillary & Immersible

Go to Autotest Division >

Go to Autotest Division >