Direct Mass Flow or Volumetric: The Thermal Flow Meter Technology Advantage!

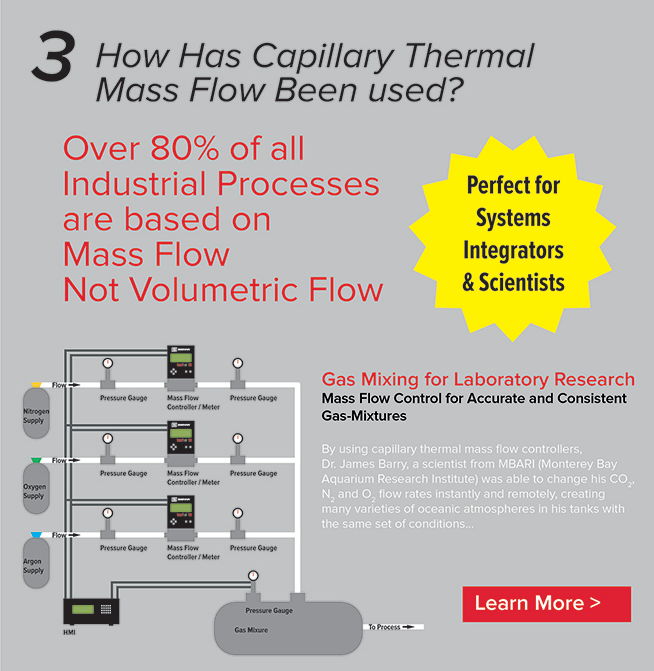

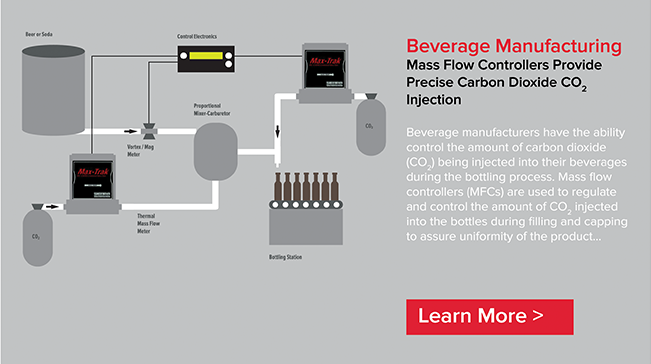

In today’s world where everyone is watching the bottom line, you need high performance, cost-effective instrumentation—and capillary thermal mass flow meters and controllers have been proven to meet this criteria in a wide range of process applications.

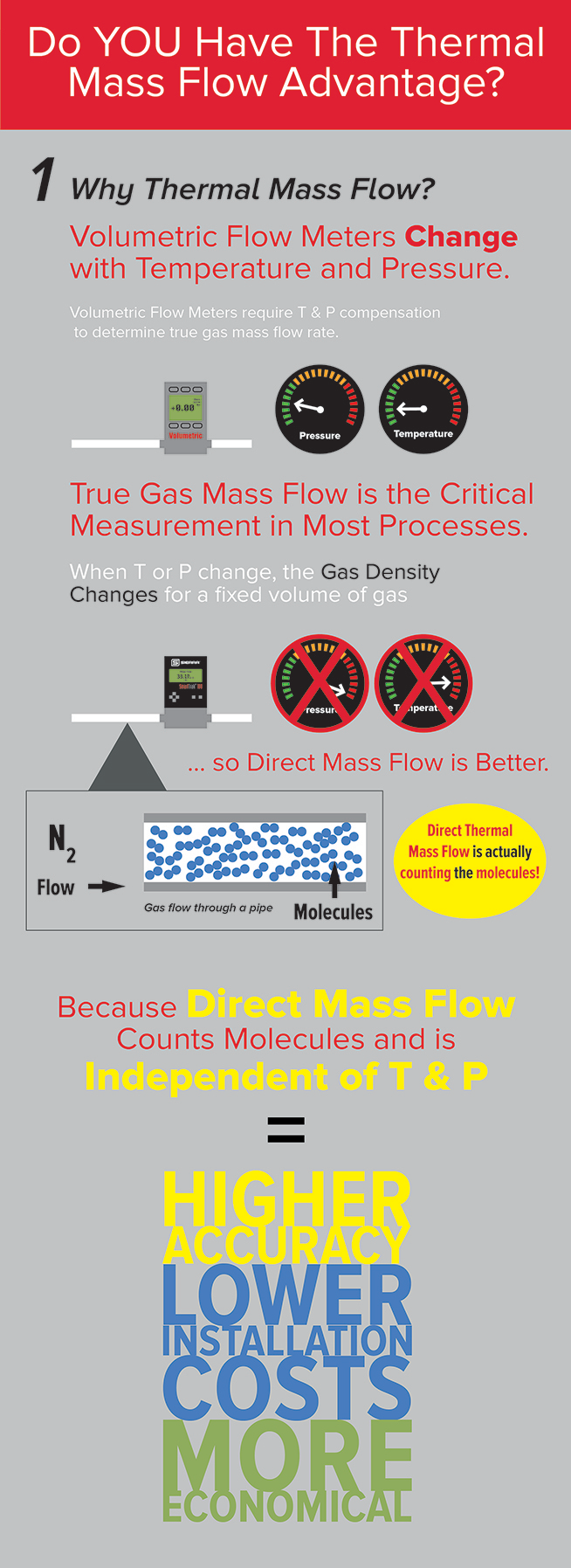

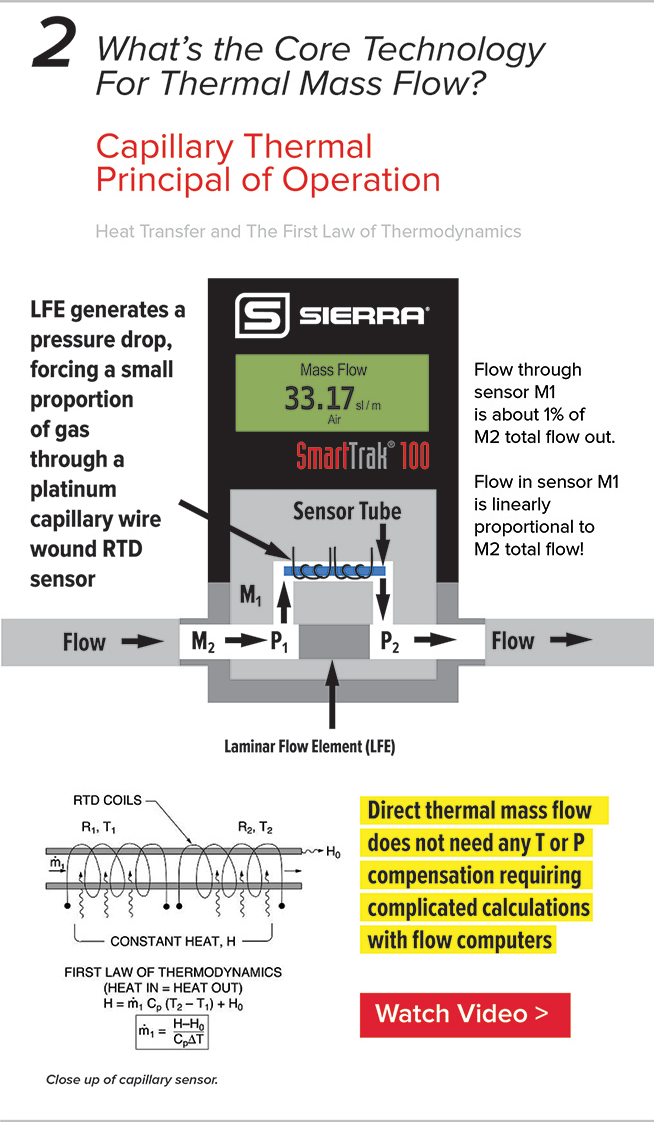

Thermal mass flow technology is an industry standard for mass flow control of gases because it measures flow directly, at the molecular level. In most processes flowing gases like Air, Argon, CO2, N2, Etc., it is gas mass, not gas volume, which is the critical variable of most interest.

Volumetric flow measurements are less reliable than mass flow measurements because changes in gas temperature and pressure effect measurement performance. You lose accuracy and you lose reliability and in many cases even money due to process inefficiency and waste. Volumetric flow meters need additional temperature and pressure compensation to convert the volumetric flow rate into mass flow rate.

Gas flow measurement and steady control of mass flow rate with capillary thermal technology is the cleanest choice.

No messy calculations or T & P compensation, just pure physics at work for you.

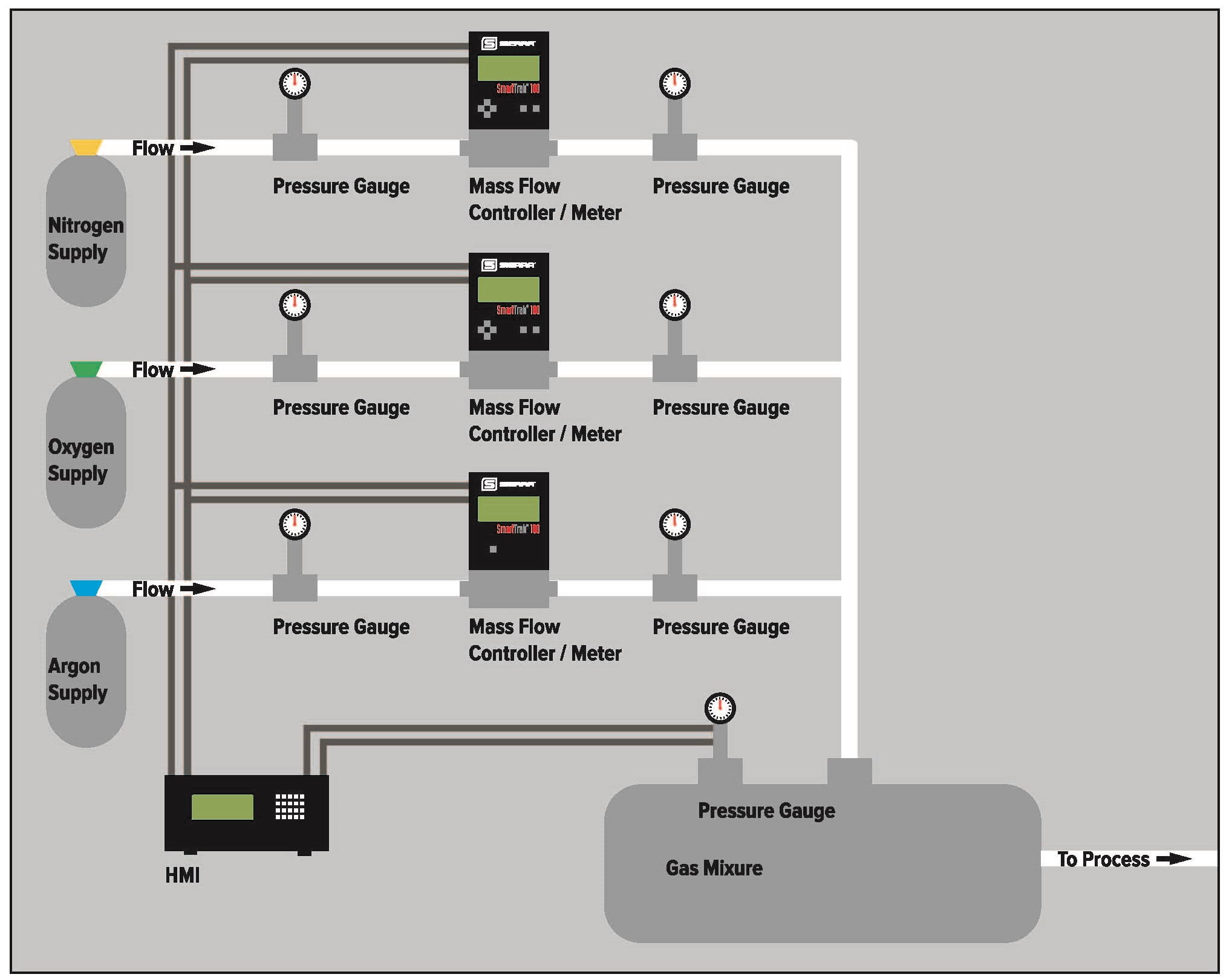

Check out our infographic below to see the thermal mass flow advantage for yourself.

|

|||||||||||||||

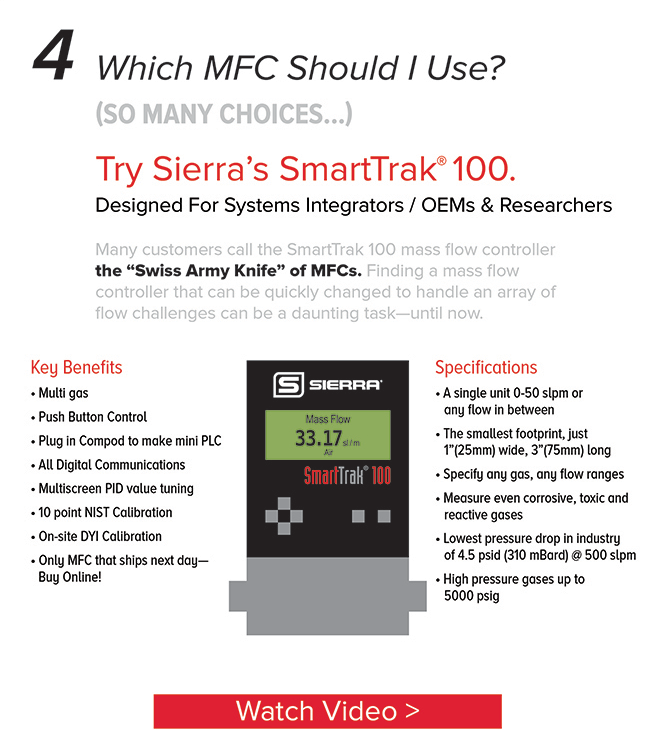

Need more info? Find out more about Sierra’s gas mass flow meters and controllers with application flexibility and proven performance for lab researchers, system integrators and more.

Go to Autotest Division >

Go to Autotest Division >