How a Vortex Flow Meter Works

Vortex flow meters are increasingly becoming the flow technology of choice for gas, liquid, and steam flow measurement. Vortex flow meters are ideal for measuring saturated and supersaturated steam in large facilities to improve steam production efficiency and allocation. Volumetric water flow and high flow gas measurements are also strong applications for vortex flow meters. Let’s take a closer look at how the vortex flow meter works and what makes it the ideal choice for many gas, liquid, and steam industrial flow applications.

What is a Vortex Flow Meter?

A vortex flow meter utilizes the fluid dynamics principle of vortex shedding to calculate the velocity of liquids, gases, and steam, across a wide variety of applications.

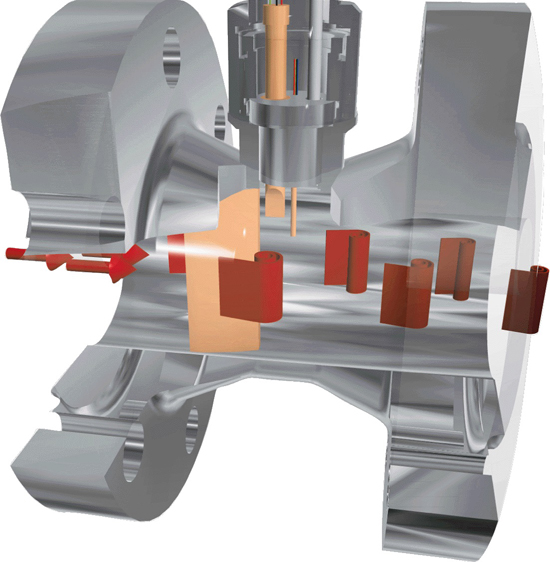

Figure 1. Vortex meter in steam measurement application.

How Do Vortex Flow Meters Work?

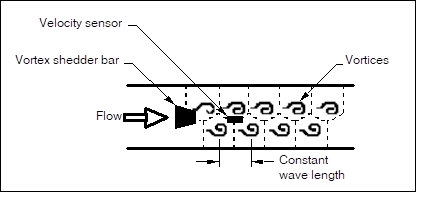

Vortex meters use a dimensioned bluff, sometimes called a shedder bar, to generate the phenomenon known as Kármán vortex street in which vortices begin to form and oscillate. Using a variety of sensor technologies, the natural frequency of these oscillating vortices is converted into a digital signal which is then processed through the meter’s electronics to calculate flow.

Figure 2. Vortex sensor cutaway showing vortex principle of operation.

Figure 3. The Von Karman Vortex Street.

Types of Vortex Sensor Technologies

Some of the sensor technologies used to measure the natural frequency produced during vortex shedding include:

- Piezoelectric crystals and ceramics - These materials produce an electrical charge in response to an applied mechanical stress. As vortices pass the sensor, they apply the stress needed for the piezoelectric material to produce a charge. Polarity may be used to distinguish the alternating current and create a digital frequency.

- Delta P sensors - The formation of vortices creates a dynamic pressure in accordance with Bernoulli’s Principle . The pressure is lowest at the point of the vortex core and increases as that point moves away from the center. By using a Delta P sensor to measure these pressure changes as the vortices pass, a digital frequency can be generated.

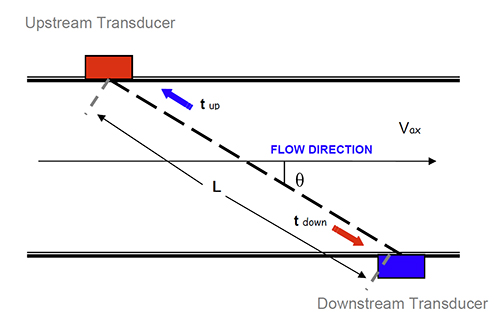

- Ultrasonic sensors - Ultrasonic sensors measure the time it takes a generated signal to travel from one transducer to another. Because the alternating vortices being shed from a bluff rotate in different directions, the signal being sent from an ultrasonic sensor will speed up or slow down based on the direction of rotation relative to the direction the signal is traveling. This shift in speed, when compared to a constant, can be used to create a digital frequency.

Figure 4. Transit-time ultrasonic principle of operation

Advantages of Vortex Flow Meters

Vortex flow meter technology offers an accurate and natural occurring method for measuring flow. Due to the natural occurrence of vortex shedding when a bluff is introduced, this method of flow measurement can be used with many types of fluids, gasses, and even steam. The lack of moving mechanical components also make for a robust construction that can hold up in some of the toughest application environments.

Is a vortex flow meter right for your application? Learn about Sierra’s vortex volumetric flow and multivariable mass flow meters to find out.

240S Inline |

240i Inline 240i Inline |

241S Insertion 241S Insertion |

241i Insertion 241i Insertion |

Go to Autotest Division >

Go to Autotest Division >