Turning Science Fiction into Reality

Precision measurement of low flow in gas mixing applications

Editor’s Note: This post was originally published on November 28, 2011. Due to its popularity and continued questions on this issue, we updated the post on March 9, 2018.

Choosing the right flow controller for laboratory or biomedical research applications is essential to achieving success in any experiment that involves controlling gas flow.

This especially holds true for gas mixing or blending applications where two or more gases are mixed (blended) in a chamber until the specified concentrations (or partial pressures) of each gas are achieved. Due to the complexity of the application, researchers are always in search of that holy-grail instrument that will provide them solid data they can count on.

Real-Life Example: Suspended Animation

Case-in-point, Dr. David Kraus, Ph.D., a sulfide biologist at the University of Alabama, was conducting cutting-edge research in the realm of suspended animation. He had concerns about the ability to accurately measure mixed gases at the necessary low flows of his experiment.

His experiment required a mass flow controller that could deliver precise and repeatable amounts of hydrogen sulfide (H2S) to laboratory mice in an attempt to induce suspended animation. This special gas involves a blend of 5% hydrogen sulfide and 95% balance nitrogen mixed into another stream of combined air and N2 at a very low flow range of 1-10 sccm. This mix was intended to slow metabolism, decrease heart rate and lower temperature.

Too much H2S would kill the mice, while the right amount induces suspended animation. Like something akin to a sci-fi movie, Dr. Kraus was “freezing” the animals in time. Removing the H2S brought them back to life.

Perfect Gas Flow Measurement Required

The challenge was finding a flow controller that would alleviate Dr. Kraus’ well-founded concerns about the ability to accurately measure mixed gases at low flows.

With traditional mass flow controllers, gas mixtures are notorious for inaccuracy. During calibration, most instruments are “curve-fit” to the application because they are not linear. They are calibrated with a primary gas, but a gas mixture has different properties than the primary gas, so the original curve is not correct for the mixture.

Accounting for pressure changes is also difficult for some flow controllers, especially devices based on differential pressure (ΔP). Since the chamber is filled with component gases, the pressure will increase, which will result in back pressure at the measuring instruments. Differential pressure devices will lose accuracy as back pressure changes.

They also perform poorly with low flows because they require a pressure drop to operate. At low flows, a low-pressure drop occurs, so the sensitivity of the meter may not be enough.

Mass Flow or Volumetric Flow

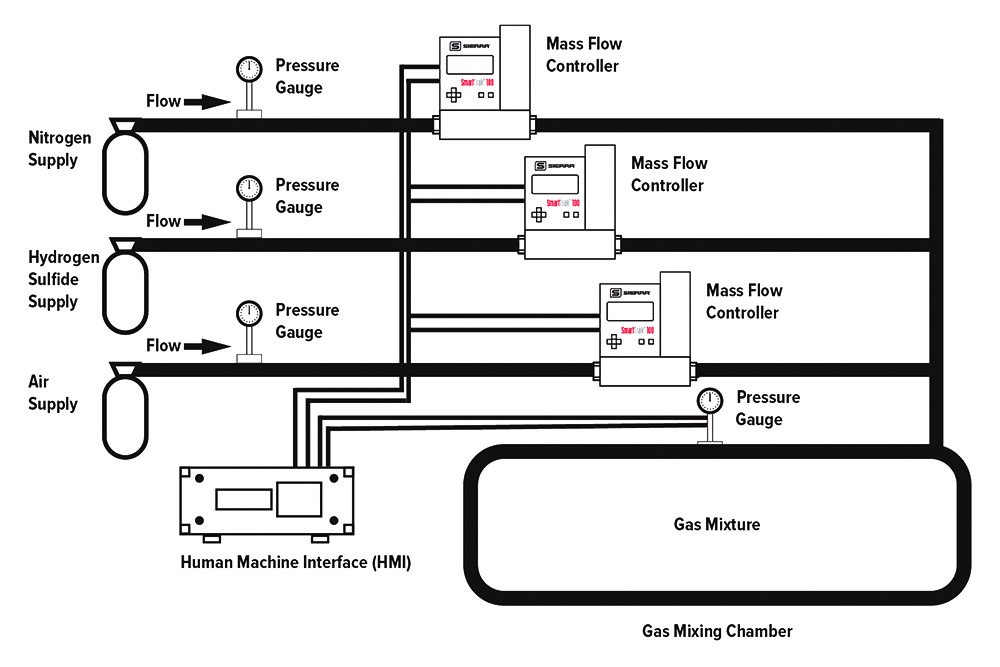

Example of a typical gas mixing application

Dr. Kraus had two choices: Mass flow or volumetric flow. Based on the known benefits of capillary thermal technology, he chose a gas controller based on mass flow technology with dial-a-gas capability and advanced laminar flow technology. Laminar flow technology creates a linear relationship that allows the K-factors programmed into the mass flow controller to correct for any gas blend over the entire flow range.

This enables the dial-a-gas capability, allowing identical controllers to control the various pure gases that make up the mixture and deliver the mixture, all without recalibration. This type of linearity means the mass flow controller is only calibrated at zero and full scale.

Dr. Kraus used the onboard dial-a-gas capability to program a custom listing for his 5% H2S blend. Then in the laboratory, Dr. Kraus could select this programmed mixture from the dial-a-gas menu or use the same instrument to measure any of the other nine preprogrammed gases.

In addition, the powerful solenoid valve of the mass flow controller provides precision control and accuracy even at the very low flow range of 1 to 10 sccm. This low of a flow rate is difficult to obtain with differential pressure devices since low flows do not generate much pressure drop to begin with.

Because of the inaccuracies at low flow, using differential pressure devices for this experiment could have resulted in the delivery of too much hydrogen sulfide. Instead, the experiment was a success. No mice died from the toxic H2S gas and all the subjects reached suspended animation

Kraus's gas flow meter of choice met his three key requirements:

1. Precision. Too much H2S and the animals would die. Too little and he could not achieve suspended animation. The dose had to be exact - within just 1%.

2. Ease of Use. Because of the delicate nature of his experiments, Dr. Kraus wanted a gas mass flow controller that was simple and intuitive.

3. Ability to Handle Special Blends. Hydrogen sulfide is not among the standard gases most flow meters can measure.

From the lab to outer space

Dr. Kraus’s experiment was a success. He observed a suspended animation-like state in his laboratory mice. According to Dr. Kraus, these breakthroughs in suspended animation will not only change the medical field, but now NASA plans to use suspended animation for cryosleep chambers so astronauts can hibernate while traveling long distances in space.

To learn more about this groundbreaking experiment, see Scott Rouse's editorial in Flow Control Magazine.

Go to Autotest Division >

Go to Autotest Division >