Air May Be Free, But Compressed Air Isn’t! (Part 1 of 2)

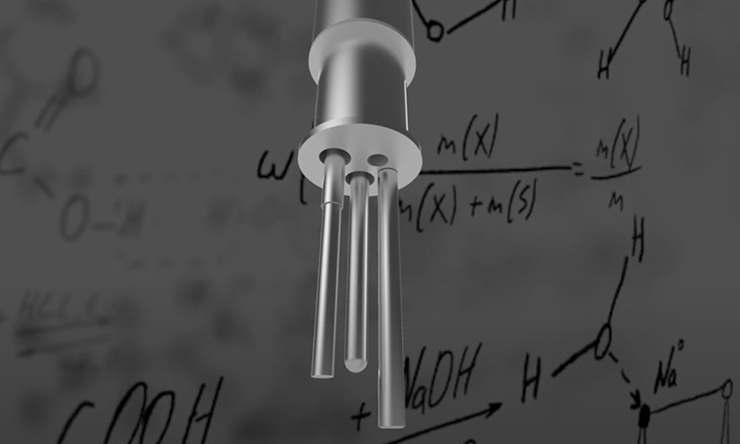

[caption id="attachment_606" align="alignright" width="180"] Insertion Thermal Mass Flow Meter[/caption]

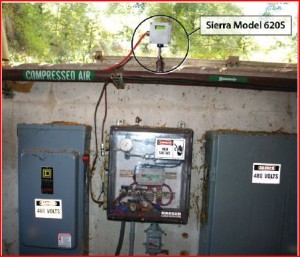

Like you, I have become painfully aware of the increasing costs of energy in our daily plant operations. Recently, I was contacted by a company in Oklahoma with an interesting application. Air Compressor Supply Inc. of Tulsa, Oklahoma, does compressed air auditing. I asked the technician, Carl Carlisle, what exactly that meant. His explanation was to-the-point: "ACS makes money by showing our customers how investing in one of our more energy-efficient air compressor saves them money in energy costs. I need a good instrument to measure compressed air."

Insertion Thermal Mass Flow Meter[/caption]

Like you, I have become painfully aware of the increasing costs of energy in our daily plant operations. Recently, I was contacted by a company in Oklahoma with an interesting application. Air Compressor Supply Inc. of Tulsa, Oklahoma, does compressed air auditing. I asked the technician, Carl Carlisle, what exactly that meant. His explanation was to-the-point: "ACS makes money by showing our customers how investing in one of our more energy-efficient air compressor saves them money in energy costs. I need a good instrument to measure compressed air."

I explained to Mr. Carlisle that this is a fairly common application. I noted, "We have had a lot of customers these last few years realize that compressed air isn’t exactly free."

Carlisle defined his application a bit more: "I need a compressed air flow meter that can measure from full compressor output to very small flows so I can find leaks from worn seals and the like, plus the thing has to be easy to install and use. We have looked at insertion turbine meters but they won’t measure the small flows and we have looked at insertion pitot tubes but I need direct mass flow. Thermal looks like a good fit."

In my next post, I will discuss reasons why immersible thermal mass flow meters fit this application well…. Insertion Thermal Mass Flow Meter[/caption]

Like you, I have become painfully aware of the increasing costs of energy in our daily plant operations. Recently, I was contacted by a company in Oklahoma with an interesting application. Air Compressor Supply Inc. of Tulsa, Oklahoma, does compressed air auditing. I asked the technician, Carl Carlisle, what exactly that meant. His explanation was to-the-point: "ACS makes money by showing our customers how investing in one of our more energy-efficient air compressor saves them money in energy costs. I need a good instrument to measure compressed air."

Insertion Thermal Mass Flow Meter[/caption]

Like you, I have become painfully aware of the increasing costs of energy in our daily plant operations. Recently, I was contacted by a company in Oklahoma with an interesting application. Air Compressor Supply Inc. of Tulsa, Oklahoma, does compressed air auditing. I asked the technician, Carl Carlisle, what exactly that meant. His explanation was to-the-point: "ACS makes money by showing our customers how investing in one of our more energy-efficient air compressor saves them money in energy costs. I need a good instrument to measure compressed air."

Go to Autotest Division >

Go to Autotest Division >