Part 1: Challenges with Submetering Natural Gas

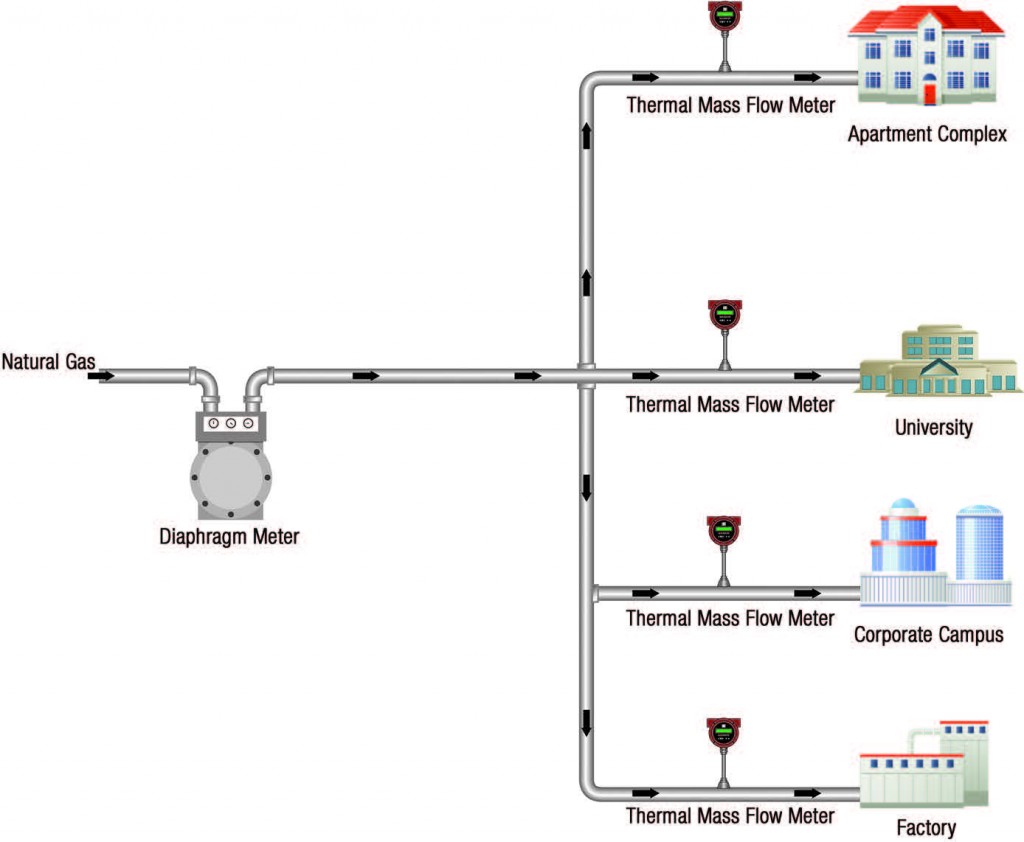

The most common type of gas meter, seen in almost all residential and small commercial installations, is a diaphragm meter. Utility companies use diaphragm meters to measure the flow rate of natural gas and monetize the usage for billing. Within the meter, there are two or more chambers formed by movable diaphragms. With the gas flow directed by internal valves, the chambers alternately fill and expel gas, producing a near continuous flow through the meter. As the diaphragms expand and contract, levers connected to cranks convert the linear motion of the diaphragms into the rotary motion of a crank shaft, which serves as the primary flow element. This shaft can drive an odometer-like counter mechanism or it can produce electrical pulses for a flow computer (a smart meter).

Diaphragm gas meters are positive displacement meters. These gas meters measure a defined volume, regardless of the pressurized quantity or composition of the gas flowing through the meter. Temperature, pressure and heating value compensation must be made to measure the actual amount and value of gas moving through a meter. These fixed compensation variables used by utility companies can yield inaccuracies and overcharging of utility bills. For example, the diaphragm meter typically measures the natural gas volume in hundreds of cubic feet (CCF); however, the consumer is billed in therms, where one therm is equal to 100,000 BTUs. Customers are billed by taking the gas meter reading in cubic feet, converting this value to therms, then applying a multiplier that is the product of the heat value of the gas (composition dependent) times the gas density (pressure dependent). The fact is that these multipliers are not accurate. As mentioned, the diaphragm meter is a volumetric meter, while natural gas is sold on the basis of mass. Volumetric meters cannot account for changes in gas composition nor deal with changes in pressure and temperature (and hence density). Such changes must be corrected for, and the consumer is at the mercy of the utility company to make those corrections.

Even though traditional thermal flow meters outperform volumetric meters due to relative immunity to changes in gas supply line pressure and temperature and no moving parts, they cannot automatically adjust for changing gas composition. When there is a large composition change, the meter must be returned to the factory for recalibration to remain accurate. However, a solution for this problem has recently emerged. Four-sensor thermal technology now provides a method for dealing with changing natural gas compositions in the field.

In my next blog post, I'll share more about this innovative four-sensor mass flow meter branded by Sierra as QuadraTherm. Why will it prove to be so valuable to facilities submetering their natural gas usage now and in the future? For more in-depth information about natural gas submetering, download the article today. And, find out how you could slash your facility's natural gas bill in our sub-metering infographic.

Go to Autotest Division >

Go to Autotest Division >