Thermal Mass Flow Meters Improve Efficiency in Wastewater Treatment Plants

Every municipality throughout the country has a wastewater treatment plant to safely treat water that enters back into our environment. This doesn’t mean they are immune to problems. One of the biggest problems for US wastewater treatment plants is the aging infrastructure with an estimated 180 billion dollars needed to repair many wastewater plants. A close second is the energy needed to successfully run a plant. Wastewater treatment plants consume between 3% to 15% of the nation’s electrical power every year.

To solve these problems, plant operators must update instrumentation and find creative ways to both save and produce energy. Selecting the best flow meter for key processes such as aeration and using biogas for cogeneration can help the cause of cutting operation and energy costs.

Thermal Mass Flow Meters Optimize Air Flows to Aeration Basins

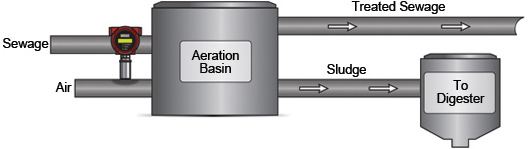

Up to 60% of the energy used by wastewater treatment plants is from the aeration process. In this critical and costly secondary stage of wastewater treatment, blowers aerate the basins, removing about 85% of the organic matter by making use of the bacteria living within it. Municipalities need precise mass flow measurement instrumentation to bubble the exact amount of air into these aeration basins for the bacteria to flourish.

Aeration Basin Control

In the past, many municipalities used differential pressure (dP) devices to measure the mass flow rate of air delivered to their aeration basins, but these devices proved to be expensive to maintain, clogged easily, measured only volumetric flow, and required a separate pressure and temperature transducer and flow computer to deliver true mass flow. Immersible thermal flowmeters are the ideal choice to measure the direct mass flow of air bubbling into the aeration basins. By using thermal flow meters as a key input into the control loop wastewater treatment plants can save up to 50,000 dollars per year in aeration costs and a reduction in chlorination and pH adjustments.

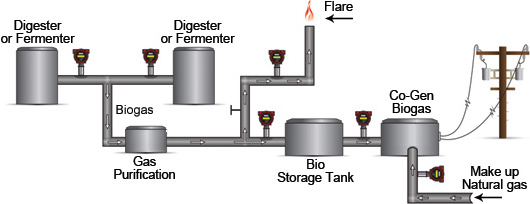

Thermal Mass Flow Meters Measure Digester Gas for Cogeneration

To reduce emissions and produce clean energy to offset high electric bills, solid wastes are often digested in large digester tanks to reduce the volume of waste (sludge) and produce more biogas, which is then used as fuel in the cogeneration process. However, a clean environment calls for not just clean air and clean energy, but clean water as well.

Most wastewater treatment plants produce abundant, healthy amounts of biogas each day in their digesters. Acting like a large stomach, the solids from the treatment process are "digested" in four large domed digesters and heated to 98 degrees. When methane forming bacteria break down the acids in the digester, large amounts of anaerobic digester gas, made up of 60% methane and 40% CO2 are produced. Once cleaned, compressed and mixed with natural gas, this biogas becomes a valuable fuel for a plant's co-generators, which produce enough electricity to meet over 50% of the plant's electrical needs.

Digester gas is produced at low flow rates, so meters that can measure very low flows are required. Low flows create a very small differential pressure across a differential pressure (dP) device such as an orifice plate or annubar, so the flow signal often becomes lost in the noise of the measurement. Immersible thermal mass flow meters overcome the inherent weaknesses of dP devices by measuring true mass flow directly with a high turndown (100:1) and virtually no pressure drop.

In a small way, thermal mass flow meters help with the major concerns plaguing wastewater operations managers by reducing costs of aeration and creating energy from biogas which reduces energy costs.

Benefits of Immersible Thermal Flow Meters

Sierra’s Immersible thermal flowmeters have become the technology of choice for measuring digester gas, biogas, and air to aeration basins in wastewater treatment plants. They are easy to install, just insert the probe into the pipe and get direct mass flow readings.

- Has the highest accuracy rating in the market (+/- 0.75% of reading)

- Offers 100:1 turndown for accurate monitoring of peak and low flow situations

- In-line flow condition eliminates piping straight-run requirements

- Generates minimal pressure drop across the meter

- Patented Dry-Sense™ Sensor Technology prevents sensor drift

Learn more about flow meter technology for Wastewater Treatment Facilities.

Go to Autotest Division >

Go to Autotest Division >