How Do MEMS Mass Flow Controllers Work?

Not All MFC Sensor Technology is Created Equal

Mass flow controllers offer precision gas flow control to many critical industries including biopharm, semicon, food & beverage, manufacturing, and R&D. As the technology demands increase in these sectors, so does the demand for precision gas flow control systems. The more accurate and repeatable the gas flow control the better the yield, the higher the product quality and the lower the cost in wasted materials.

So what mass flow control technology offers the highest accuracy and repeatability over time? MEMS (Micro-Electro Mechanical Systems) sensors offer the most stable and accurate gas flow control in the industry. Mass flow controllers and meters based on MEMS technology don't drift like other technologies, offering OEMs and bioprocessing applications a mass flow controller that is accurate over the lifetime of the device-no yearly recalibration or process shutdown necessary.

How does MEMS technology work to ensure a "no-drift" mass flow controller?

MEMS Principle of Operation

MEMS technology utilizes an advanced, ultra-stable, no-drift CMOS (Complementary Metal Oxide Semiconductor) sensor. The CMOS sensor houses both the electronic circuits and mechanical elements on a silicon chip, similar to the process used for integrated circuits.

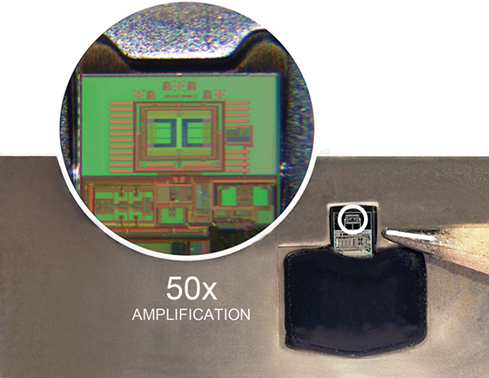

Sierra's RedySmart MFC - MEMS Sensor at 50x Amplification view

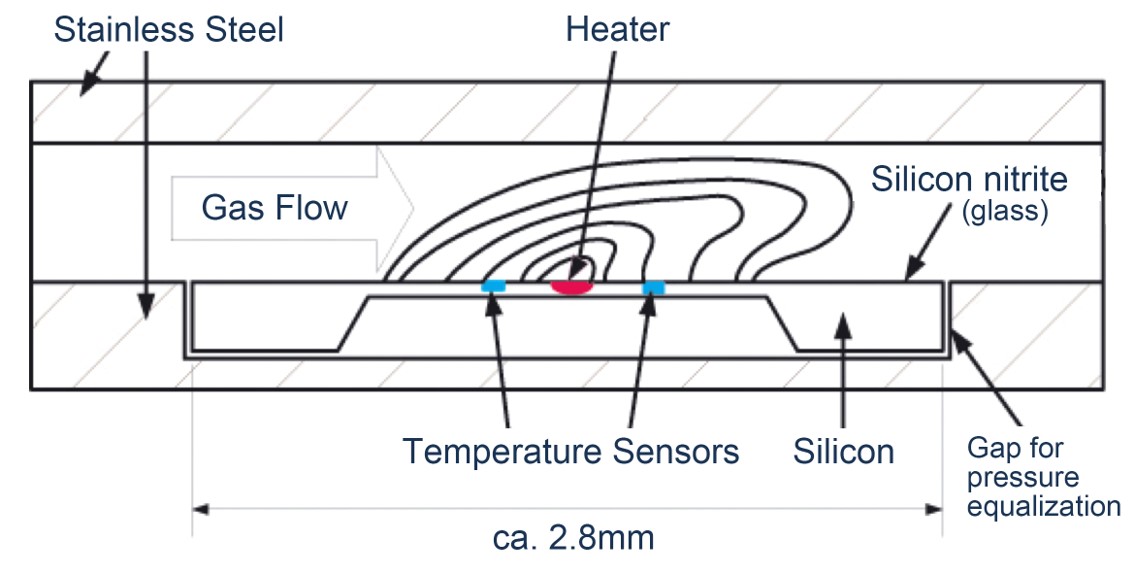

MEMS technology is based on the thermal principle of operation. MEMS sensors consist of two or three temperature sensors and a heater. Through vapor deposition, an extremely small molecular layer is deposited on a thin membrane. MEMS-based mass flow controllers have a bypass that pushes a defined percentage of the total gas flow through the sensor. The bore of the sensor is fairly large, so that the pressure drop is relatively low. In the presence of flow, the MEMS chip introduces heat into the medium with a constant heating output. The two temperature sensors are arranged symmetrically before and after the heating element to detect a shift in the temperature profile towards the downstream sensor of the heating element. If there is no flow, both sensing elements measure the same temperature. Because the sensor is part of the MEMS electronic circuit, the measured signal is immediately digitized giving direct mass flow readings.

Why Mass Flow is Critical

Measuring mass flow is important since most processes are more directly related to mass flow rather than to volumetric flow. For respiration, fermentation or any chemical process, it is that number of oxygen molecules that are critical, mass not volume that is critical. Unlike turbine meters, ultrasonic, pressure differential, pitot tubes and many other devices, thermal flow meters measure mass flow. Direct mass flow meters are unaffected by fluctuations in both temperature and pressure which make them inherently more accurate than volumetric technologies.

Benefits of MEMS Mass Flow Controllers

The biggest advantage of the MEMs sensor is that there is no (measurable) drift. Drift is a slow shift of the zero and the measured value at a given flow. Drift affects the accuracy. MEMS sensors are also compatible with its electromagnetic (EM) environment and don't emit levels of EM energy that cause electromagnetic interference (EMI) distorting the signal. This along with the fact that the sensors are free of mechanical and thermal stress enables a no drift sensor and long-term device accuracy.

Mass flow controllers based on MEMs technology do not have a linear output, so they must be calibrated with the actual gas that is being used in the application. The output is a complex curve that can only be accurately curve-fit with a spline or a polynomial. And every sensor construction varies, so there is no repeatability from sensor to sensor. That means that every flow meter and controller needs to be calibrated individually on actual gas which increases their accuracy.

MEMS sensors are also very fast with a 50 msec response time with virtually no warm-up time. The instrument does not need the zero to be adjusted on regular basis. A MEMS sensor is also a lot more sensitive and due to that a turndown of 1000 : 1 is obtainable.

Benefits of MEMS Sensors

- No-drift sensor-Long term stability over a long period of use

- Wide turndown of 100:1. (Higher possible)

- Less sensitive to pollution due to big ID sensor

- Excellent temperature coefficient

- High accuracy due to real gas calibration

- Low-pressure drop (2.5 mbar at low flow)

- Built-in flexibility

- Low power consumption

RedySmart Mass Flow Controller with Lifetime No-Drift Sensor Warranty

Sierra's RedySmart thermal mass flow meters & mass controllers are based on MEMS-based (Micro-Electro Mechanical System) technology to complement our SmartTrak® capillary-based mass flow meters & gas controllers. RedySmart thermal mass flow devices contain no moving parts and are unaffected by upstream temperature and pressure fluctuations, resulting in exceptional accuracy and repeatability.

RedySmart Proven & Stable Mass Flow Controllers offer OEMS:

- Lifetime no-drift sensor warranty - if drift occurs, instrument will be repaired or replaced free of charge

- High Accuracy up to ± 0.3% of full scale ±0.5% of reading

- Repeatability of +/- 0.2% of full scale

- Air, N2, O2 are standard. Other non-toxic, non-corrosive gases available upon request.

- Custom and compact gas mixing blocks

- MEMS (Micro-Electro Mechanical Systems) with ultra-stable no-drift CMOS (Complementary Metal Oxide Semiconductor) sensor

- Ideal for OEM Applications-optimized for BioPharm/Burner Control

- Modular-customize to needs. An easy-connect communication and power cable system has been designed for ultimate flexibility

Learn more about MEMS Sensor technology and RedySmart products.

Discover how MEMS sensor technology is providing edge to accelerate bioprocessing from pilot to production.

Go to Autotest Division >

Go to Autotest Division >