Economical Clamp-On Ultrasonic Water Flow Meter for Accurate Results

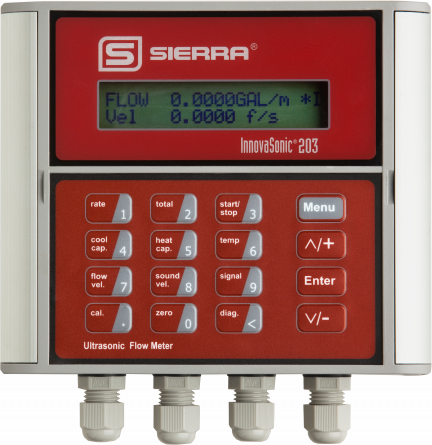

InnovaSonic®203

- High performance at an affordable price

- Simply clamp-on outside of pipe for easy set up

- Save time with no pipe cutting or process shutdown

Overview

The InnovaSonic 203 liquid flow meter is optimized for customers still looking for high performance, but needing a lower-cost, less feature-rich option for dedicated clamp-on ultrasonic metering. The 203 digital liquid flow meter optimizes the measurement of water as it flows in HVAC, irrigation and other liquid applications.

Common Applications:

|

|

The InnovaSonic 203 digital flow meter:

- Uses universal transit-time digital signal processing to offer excellent accuracy and repeatability for a wide variety of liquids

- Determines the velocity of the fluid by measuring the time it takes an ultrasonic signal to travel a known distance with the flow stream, and another signal travelling against the flow stream

- Features measurement that is independent of fluid conductivity to allow a wider applicability compared to magnetic meters

In addition, a programmable frequency output and VAC power emulates turbine/propeller meters for easy replacement or decommissioning of older technology flow devices.

Product Benefits

|

|

Specifications

|

|

Documents & Downloads

Datasheets(2) | |||

| File Title | Version | Release Date | |

|---|---|---|---|

InnovaSonic 203 Technical Datasheet | H | 01/22/2025 | |

InnovaSonic Application Datasheet (ADS) | V4 | 06/17/2020 | |

Guides(1) | |||

| File Title | Version | Release Date | |

InnovaSonic 203 Quick Install Guide | E | 12/13/2018 | |

Digital Communications - Flow Meter Digicom - Modbus RTU(1) | |||

| File Title | Version | Release Date | |

InnovaSonic 203 Instruction Manual | L | 02/22/2023 | |

Certificates(1) | |||

| File Title | Version | Release Date | |

| InnovaSonic Series CE Certificate of Conformity | 1.0 | 09/01/2011 | |

White Paper(1) | |||

| File Title | Version | Release Date | |

Application Tech Note: Get The Key To Water Savings | V1 | 01/10/2019 | |

Additional Documentation(6) | |||

| File Title | Version | Release Date | |

| Sierra Clean Energy Guide | V1 | 01/28/2011 | |

| Full Line Catalog - German Version | V1 | 08/07/2017 | |

| Service Brochure | 2.0 | 04/06/2015 | |

| Terms and Conditions | 1.0 | 11/01/2010 | |

| Warranty Statement | 2.0 | 04/01/2015 | |

Full Line Product Offering | V4 | 08/03/2023 | |