Part 2: Challenges with Submetering Natural Gas

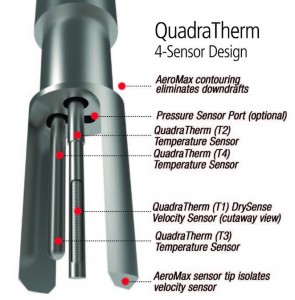

Four-sensor Thermal technology by Sierra Instruments provides a method for dealing with changing natural gas compositions and density changes caused by pressure variations. This flow meter corrects for density variations using the AGA Report No. 8-approved density equations for natural gas. Instead of having two sensors, one a temperature sensor in the temperature probe and the other, a self-heated sensor in the velocity probe, there is an additional sensor strategically located in each, giving a total of four sensors. The extra temperature sensors in the stem of each probe measures the stem conduction, which is a function of the total heat transfer budget and must be accounted for. Stem conduction depends on the ambient temperature outside of the pipe (See Figure ).

Four-sensor Thermal technology by Sierra Instruments provides a method for dealing with changing natural gas compositions and density changes caused by pressure variations. This flow meter corrects for density variations using the AGA Report No. 8-approved density equations for natural gas. Instead of having two sensors, one a temperature sensor in the temperature probe and the other, a self-heated sensor in the velocity probe, there is an additional sensor strategically located in each, giving a total of four sensors. The extra temperature sensors in the stem of each probe measures the stem conduction, which is a function of the total heat transfer budget and must be accounted for. Stem conduction depends on the ambient temperature outside of the pipe (See Figure ).

Go to Autotest Division >

Go to Autotest Division >