Tuning Your Boiler for EPA Boiler MACT Compliance

The EPA’s Boiler MACT (Maximum Achievable Control Technology) regulations are heating up. Boiler MACT is an EPA rule to limit hazardous air pollutants (HAP) from commercial and industrial boilers and process heaters. Originally published in 2011 as a mandate driven by the Clean Air Act, the rules are Area Source Boiler MACT 40 CFR 63, subpart JJJJJJ for smaller boilers (stores, hotels, apartments, small manufacturers, etc.) and Major Source Boiler MACT, subpart DDDDD for large ones (refineries, chemical and large manufacturing plants, large facilities).

Annual boiler compliance reports, efficiency tuning, and energy assessment are all buzz words, and facilities managers need to act fast to comply with the Boiler MACT regulations. This urgency is fueled further by the upcoming Major Source Boiler MACT final compliance deadline of January 31, 2017—which ends the three-year grace period from the date the final rules were published.

Boiler Tuning Increases Efficiency The thrust of the Boiler MACT standards requires end users to report boiler emissions, a rule which has already been adopted in most states (See Figure 1). The addition to the mandate requires end-users to “tune” new boilers when they first start up and then perform periodic tuning.

The good news is that the purpose of the "tuning" is to measure boiler efficiency. How efficient is the boiler at turning the fuel (oil, gas, coal) and water into steam? A well-tuned boiler is around 80% efficient. If the boiler's efficiency is less than 80%, then energy is being wasted and most likely adding hazardous air pollutants to our environment. In this case, end users are required to fix the boiler to meet this efficiency level. “Fixing it” entails fixing leaks, adding insulation, and cleaning heat exchanger tubes, which all add to the cost of boiler maintenance. Download Boiler MACT Information Guide.

3 Ways to Tune Your Boiler for Boiler MACT Compliance

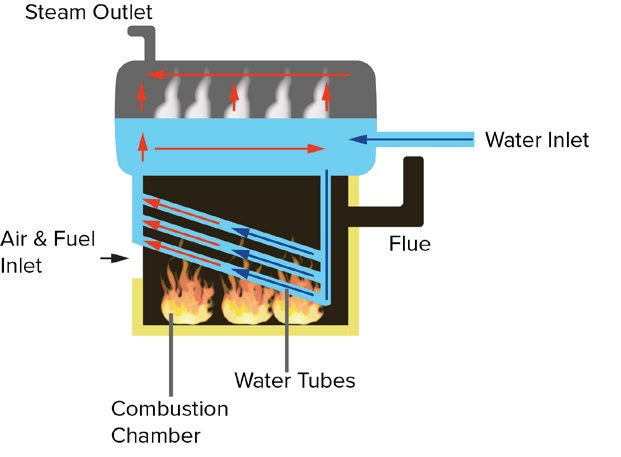

To efficiently tune a boiler, three key measurements must be taken: air and fuel inlet flow, feed water flow, and steam output (See Figure 1).

Figure 1: Typical Boiler Flow Application

The ideal instrumentation to provide these flow measurements for tuning are thermal flow meters for gas, ultrasonic flow meters for water, and vortex flow meters for steam output. Sierra's variety of flow meters can help you manage your energy costs downward and meet EPA Boiler MACT regulations by providing solutions for the following three key measurements.

1. Measure Fuel Flow to Boilers

It's critical to precisely measure the intake fuel (oil, gas, coal) to the boiler to tune and then optimize for efficiency. Sierra’s economical BoilerTrak thermal mass flow meter, specifically designed to provide precise natural gas measurement for heaters and boilers, is an ideal product to help with monthly fuel reporting and boiler tuning to increase efficiency. For more complex gas mixtures being burned, use QuadraTherm 640i/780i thermal mass flow meters.

2. Measure Feed Water Flow to Determine Steam Efficiency

In boiler tuning, the feed water flow to the boiler is an important measurement, since you need to measure the efficiency at which the boiler turns this feed water into steam (See Figure 1). Our InnovaMass 240i vortex volumetric flow meters are an economical solution for water measurement applications in new boilers, while the InnovaSonic 205i ultrasonic flow meter can be retrofitted easily into existing boilers due to its clamp-on nature. The 210i portable ultrasonic flow meter is a good analysis tool as well for periodic boiler tuning where fixed measurement devices are not already installed.

3. Measure Steam Output

To determine the efficiency of the boiler, accurate steam measurements are critical (See Figure 1). For measuring steam output, the InnovaMass iSeries vortex flow meter in insertion and inline versions are the industry-leading vortex flow meter meter for steam measurement. With its ability to measure five process variables at the same time simultaneously, and correct for density changes in steam, the InnovaMass vortex flow meter can give an accurate assessment of the efficiency of the boiler and maximize steam productivity.

Boiler MACT Decreases Emissions

Since the intention of these Boiler MACT standards are driven by the EPA's mandate in the Clean Air Act to develop national emissions standards, the hope would be that through Boiler MACT compliance, facilities tune their boilers to ensure the maximum boiler efficiency, which in turn minimizes the source of air pollution.

Flow meter companies like Sierra can be part of this bigger solution. We can measure the air and fuel going into the boiler, the feed water, and the steam being produced. And from that flow measurement data, end-users can calculate the boiler efficiency and the greenhouse gases in the waste gas coming out of the flue—which is what these Boiler MACT regulations are trying to accomplish! Sierra has everything you need to fully comply with Boiler MACT immediately.

Learn more about Boiler MACT compliance and boiler efficiency. Download Boiler MACT Information Guide.

Download Webinar on Understanding EPA's Major Source Boiler MACT Rule.

Need additional help selecting the right flow meter for your boiler? Contact Us today.

Go to Autotest Division >

Go to Autotest Division >